A hackable, multi-functional, and modular extrusion 3D printer for soft materials

Researchers have developed a hackable and multi-functional 3D printer for soft materials that is affordable and open design. The technology has the potential to unlock further innovation in diverse fields, such as tissue engineering, soft robotics, food, and eco-friendly material processing—aiding the creation of unprecedented designs.

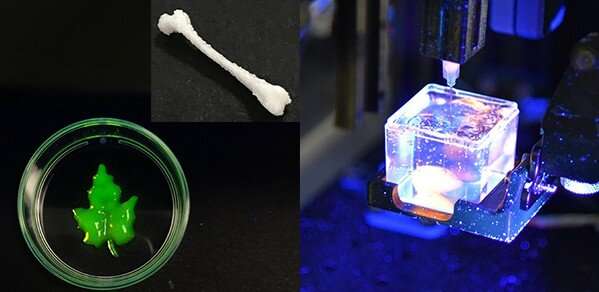

Printer.HM, as it is known, is a highly customizable extrusion-based 3D printer to rival commercial 3D bioprinters. It is capable of accepting different geometry inputs—including computer-aided design (CAD) models, coordinates, equations, and pictures—to create prints of distinct characteristics. The development of this multi-printhead system—built on a hackable robotic arm and offering multi-functionalities in one platform via heating and ultraviolet (UV) modules—is the brainchild of researchers from the Department of Engineering, University of Cambridge, and The Nanoscience Center, University of Cambridge, in collaboration with the Universities of Macau and Oxford. Details of their affordable printing approach are reported in the journal Scientific Reports.

In addition to offering excellent print compatibility with a wide variety of liquidous and soft materials, a multitude of operations can be performed, including:

- Liquid dispensing

- Multi-material printing

- Printing with variable speed

- Embedded printing (creating freeform and overhanging structures)

- Non-planar printing

- Pick-and-place application.

With the optional heating and UV modules, the printability of thermal-responsive and photo-polymerizable hydrogels can be tuned, and these are of use in a wide range of biomedical applications including drug delivery, tissue engineering and wound healing.

Printer.HM offers its user the design freedom and ability to customize the print path to create prints of distinct characteristics. These are: simple patterns (coordinates); one stroke printing (equations); 3D designs (G-code); and customizable 2D motifs (pictures), the latter can easily convert hand-drawn sketches into prints without the need to create a CAD model. Print path customizability is especially useful for soft robotics applications, as demonstrated by the researchers' creation of a soft morphing system made of a pH-responsive hydrogel.

The researchers used Printer.HM to create a 2D sketch of a flower motif that then swelled and morphed into a 3D flower shape within four minutes. And this is just the beginning; because the control program is entirely hackable, users can reconfigure the setup and expand its functionalities for 3D printed designs never achieved before. The researchers also demonstrated the potential of Printer.HM to generate sophisticated tissue anatomy, by successfully creating a model of the respiratory system with lungs and trachea, made of alginate inks, and printed inside a support bath.

Dr. Iek Man Lei, first author and an Assistant Professor at the University of Macau, is a former Ph.D. student from the Biointerface Research Group at Cambridge.

Dr. Lei said, "The versatile functionalities of Printer.HM, together with its open design and affordability (a total cost of between £900 and £1,900), make it a credible option for the future of 3D printing innovation using soft, biological and sustainable material architectures. The modular design allows the research community to expand the functionalities of Printer.HM further, opening up the possibility of endless new designs. Other benefits include compatibility of the printhead with syringes of a smaller size that are desirable in small-scale biological applications, and ease-of-use for those without CAD experience to customize the print path using the picture geometry input—this is particularly beneficial for controlling the morphing behaviors of stimuli-responsive hydrogels."

She added, "Printer.HM has the potential to open the door to innovative 3D printing in diverse fields, such as tissue engineering, soft robotics, food, and eco-friendly material processing. Its open design, affordability, improved customizability and all-in-one functionalities will benefit the do-it-yourself research community, providing a viable alternative to existing commercial printers."

More information: Iek Man Lei et al, A hackable, multi-functional, and modular extrusion 3D printer for soft materials, Scientific Reports (2022). DOI: 10.1038/s41598-022-16008-6