Improving the interfacial binding in flexible electronics is crucial for commercialization

Stretchable electronic devices are promising candidates for personalized health care systems. The research on using them in various medical and bio-monitoring applications has drawn great attention from scientists all over the world. Though very useful, there is still not even a single mature and well-known stretchable electronic device on the market.

One reason is the high cost of the devices (from the materials and manufacturing methods) limits the accessible customers; another important reason is the weak interconnect in stretchable electronics restricts their stability and reliability at a level much lower than that of existing commercial devices.

The weak interconnects are derived from the distinct properties among different stretchable units and materials. The mismatch of the units' mechanical properties led to concentrated stress and strain at their interfaces during deformation; while the chemical difference of the materials resulted in weak interfacial binding strength that could not sustain the consequences of mechanical mismatch.

Together, a fully integrated stretchable device could easily fracture at the heterointerfaces connecting different units during its function and flexible deformation.

With a view to this problem, a review, written by Prof. Xiaodong Chen and Dr. Shaobo Ji (School of Materials Science and Engineering, Nanyang Technological University), has summarized existing strategies addressing the weak interfacial binding and discussed the future research directions toward commercialized flexible devices.

The strategies were summarized into two catalogs: chemical—covalent bonding, and physical—mechanical interlocking. The chemical methods could produce covalent linkages at the interfaces between different stretchable units and materials, by growing a unit composed of polymers on the substrate unit with "seeds" (reactive initiators or monomers), or by the connection of "sticky tips" (complementary reactive groups) on different surfaces.

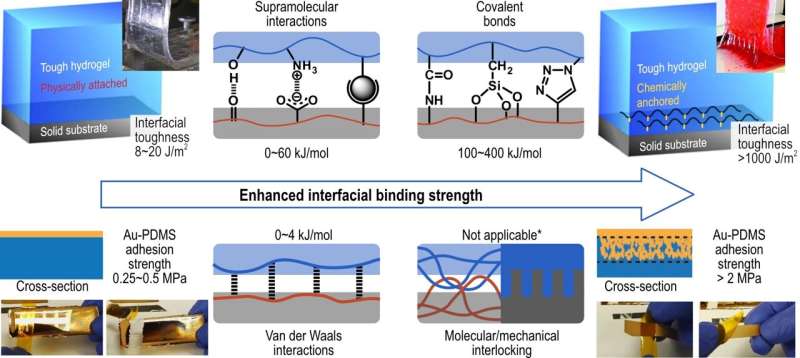

The covalent bonds could provide much higher interfacial toughness and are efficient for improving the interfacial bindings (see image, upper part), however, not all materials and units are suitable for the chemical reactions and modifications required for forming covalent linkages. In these cases, physical strategies have been developed.

Two general methods for different scales were summarized: "sewing" with polymer chains at the molecular level by forming interpenetrating polymer networks at the interfaces, or "hand-in-hand" holding at the nano and micro level by forming mechanical interlocking structures. The physical interactions, which are chain entanglement, van der Waals interaction with increased contact areas, friction force, etc., could as well provide enhanced interfacial strength (see image, lower part).

By summarizing these strategies, the authors not only provided a reference for researchers seeking methods to produce stable interfacial connections but also pointed out one of their existing drawbacks—lack of universality. Current methods usually require the pairing of complementary parts due to the specially designed and modified surfaces.

While for conventional rigid electronics, a solder is enough for building a tough interface in most cases, and it allows the rigid electronics to almost freely integrate with each other stably. The development of a similar universal "stretchable soldering" system, which is expected to be also stable and efficient, could greatly push forward the commercialization of stretchable devices.

"A general system is desired to produce stretchable and rigid parts with universal connections so that they could be tightly connected between any two parts regardless of their materials and properties. It could pave the way for 'Lego-like' assembly of modularized stretchable devices from different functional blocks, which suits their desired applications: personalized and customized functions with massive production," the authors write in the paper.

The research was published in National Science Review.

More information: Shaobo Ji et al, Enhancing the interfacial binding strength between modular stretchable electronic components, National Science Review (2022). DOI: 10.1093/nsr/nwac172