December 9, 2022 feature

A 1.3-micrometer-thin elastic conductor for wearable and implantable devices

In recent years, engineers have been working to develop increasingly sophisticated and smaller electronic components that could power the devices of the future. This includes thin and stretchable components that could be easily worn on the skin or implanted inside the human body.

Researchers at RIKEN, Nanyang Technological University, National University of Singapore, University of Tokyo, and other institutes in Japan, Singapore and China have recently realized a new, elastic electrical conductor that is 1.3-micrometers thin. This conductor, introduced in a paper published in Nature Electronics, could advance the development of both wearable and implantable sensors.

"Ultrathin electronic devices can form a conformal interface with curved surfaces, are not perceivable by human when wearing, and do not induce strong foreign body rejection (FBR) when implanted in animals," Zhi Jiang, one of the researchers who carried out the study, told TechXplore.

"Previously, ultrathin electronic devices were constructed on plastic films, such as polyimide, parylene and SU8. However, in wearable and implantable applications, the devices can experience deformations with human skin and certain organs (e.g., the heart, muscles, and nerves), thus they need to be stretchable."

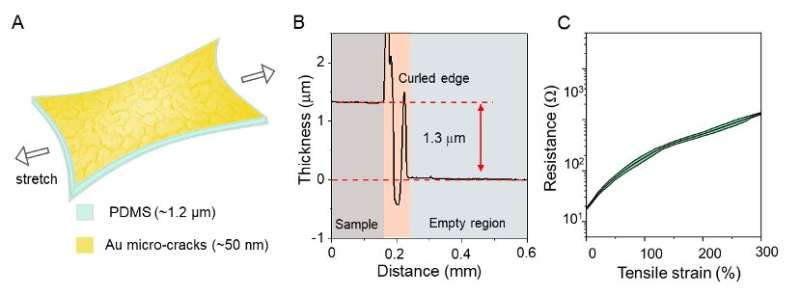

The key goal of the recent work by Jiang and his colleagues was to create a stretchable material that could support the stable operation of ultrathin wearable and implantable electronic devices for long periods of time. To do this, they created a 1.2 μm-thick film using an FDA-approved elastomer, called Polydimethylsiloxane (PDMS). They then used this film as an alternative to the plastic films typically used to create biocompatible electronic devices.

"Previously, all PDMS-Au conductors utilized thick PDMS films (ranging from tens to hundreds micrometer in thickness), which exhibited poor interfaces with textured human skin and small dimension organs (sciatic nerves and muscle bundles)," Jiang said.

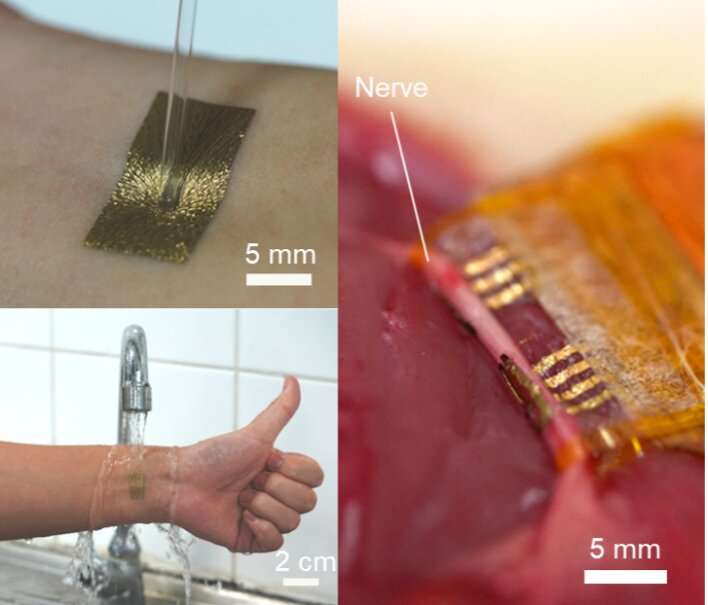

"Additionally, human skin needs to breathe at all times, and the gas permeability of the thick PDMS films is not high enough to allow this. By reducing the thickness to 1.2 μm, ultrathin PDMS films showed a high gas permeability that did not hinder the skin's breathability."

To create their elastic conductor, the researchers first created a 1.2 μm-thick PDMS film using a technique known as spin coating. They then transferred this ultrathin film onto a 100 μm-thick PDMS coated glass and thermally evaporated a 50 nm-thick layer of gold (Au).

"Using a shadow mask, we could pattern our conductors and form multichannel electrode arrays with high resolution (100 µm)," Jiang said. "Then, using another ultrathin PDMS film as the encapsulation layer, we selectively exposed small-area Au as the electrode sites. The encapsulation happened by the tight bonding of two PDMS films after the O2 plasma treatment."

Due to its unique micro-cracked design, the team's PDMS-Au material was found to be highly stretchable, far more than plastic films tested in the past. Remarkably, its fabrication process is also highly compatible with existing microelectronics manufacturing methods, which could facilitate its large-scale production.

"By comparing electrodes with different thickness for both on-skin and nerve interfaces, we demonstrated that a seamless interface can contributed to both the electrical stimulus delivery and electrical signal recording processes," Jiang said. "The interface between electronic devices and tissues are found to be extremely important for nerves for the first time. Our study and the phenomenon we uncovered should thus be insightful for the creation of other device/tissue interfaces."

The strategy for growing gold microcracks on PDMS used by Jiang and his colleagues resulted in a material that could be stretched by up to 300%, retaining its conductive capabilities. In the future, this strategy could be used by other researchers to design alternative microcrack-based stretchable materials.

In addition, the new conductor presented in this recent paper could be used to create more reliable wearable and implantable microelectronic devices. The team already used it to fabricate breathable and water-resistant electrodes that can be applied on human skin, as well as 3 µm-thin sensors that can detect mechanical forces and implantable nerve electrodes.

"We are now exploring two main research directions," Jian added. "The first is aimed at further improving the performance of our ultrathin elastic conductors from device engineering perspective. Secondly, we are working with biological scientists to explore the potential of our ultrathin elastic electronic devices as a powerful tool for understanding biological phenomena."

More information: Zhi Jiang et al, A 1.3-micrometre-thick elastic conductor for seamless on-skin and implantable sensors, Nature Electronics (2022). DOI: 10.1038/s41928-022-00868-x

© 2022 Science X Network