This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Electric vehicle batteries could get big boost with new polymer coating

Scientists at Lawrence Berkeley National Laboratory (Berkeley Lab) have developed a conductive polymer coating—called HOS-PFM—that could enable longer lasting, more powerful lithium-ion batteries for electric vehicles.

"The advance opens up a new approach to developing EV batteries that are more affordable and easy to manufacture," said Gao Liu, a senior scientist in Berkeley Lab's Energy Technologies Area.

The HOS-PFM coating conducts both electrons and ions at the same time. This ensures battery stability and high charge/discharge rates while enhancing battery life. The coating also shows promise as a battery adhesive that could extend the lifetime of a lithium-ion battery from an average of 10 years to about 15 years, Liu added.

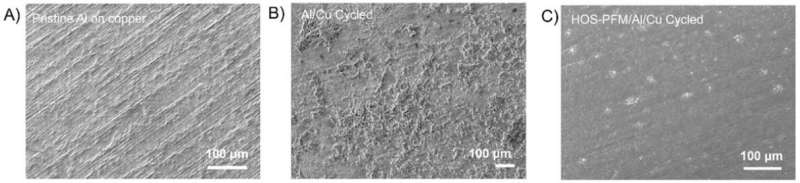

To demonstrate HOS-PFM's superior conductive and adhesive properties, Liu and his team coated aluminum and silicon electrodes with HOS-PFM, and tested their performance in a lithium-ion battery setup.

Silicon and aluminum are promising electrode materials for lithium-ion batteries because of their potentially high energy storage capacity and lightweight profiles. But these cheap and abundant materials quickly wear down after multiple charge/discharge cycles.

During experiments at the Advanced Light Source and the Molecular Foundry, the researchers demonstrated that the HOS-PFM coating significantly prevents silicon- and aluminum-based electrodes from degrading during battery cycling while delivering high battery capacity over 300 cycles, a performance rate that's on par with today's state-of-the-art electrodes.

The results are impressive, Liu said, because silicon-based lithium-ion cells typically last for a limited number of charge/discharge cycles and calendar life. The researchers recently described these findings in the journal Nature Energy.

The HOS-PFM coating could allow the use of electrodes containing as much as 80% silicon. Such high silicon content could increase the energy density of lithium-ion batteries by at least 30%, Liu said. And because silicon is cheaper than graphite, the standard material for electrodes today, cheaper batteries could significantly increase the availability of entry-level electric vehicles, he added.

The team next plans to work with companies to scale up HOS-PFM for mass manufacturing.

More information: Formation of hierarchically ordered structures in conductive polymers to enhance the performances of lithium-ion batteries, Nature Energy (2023). DOI: 10.1038/s41560-022-01176-6