This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

trusted source

proofread

A new generation of instruments for gas permeation measurement

As part of the SimPerm project, researchers at the Fraunhofer Institute for Material and Beam Technology IWS in Dresden have developed an innovative measuring technique for reliably determining the permeation rate of films. For the first time, the permeation rate of water vapor and oxygen can be detected simultaneously.

Manufacturers, users and developers of barrier films can now determine the gas permeability of barrier films for organic light-emitting diodes (OLEDs), organic solar cells, tablets, food and other air-sensitive goods more accurately, realistically and cost-effectively than before. On this basis, a partner company will soon establish a new class of instruments that can universally measure various barrier properties of films.

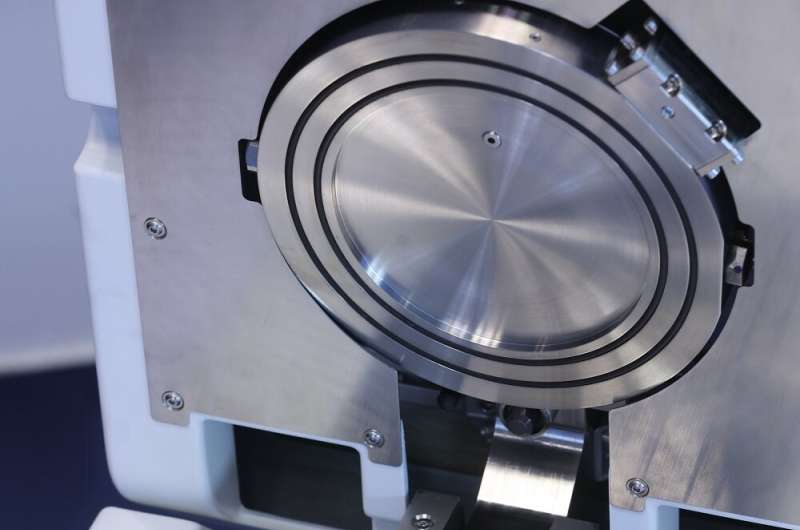

To enable the simultaneous measurement of water vapor permeation rate (WVTR) and oxygen permeation rate (OTR) in a single device, researchers at Fraunhofer IWS are combining laser diode spectroscopy for water vapor measurement with dynamic fluorescence quenching for oxygen measurement in a single measuring cell.

A simple but effective trick came into play to achieve a sufficiently low detection limit for the concentration measurement of both permeates also for ultra-barrier film: nitrogen pulses precisely control the concentrations of water vapor and oxygen molecules penetrating the barrier layer. This now discontinuous nitrogen flow can be controlled very precisely by automated opening and closing of valves. As a result, even small amounts of permeate accumulate to levels that can be reliably measured by laser spectroscopy or fluorescence quenching detectors, provided that all equilibrium conditions are maintained.

The phase durations of the nitrogen pulses and the intervening permeate accumulation are adjustable to almost any desired value. The detection limits of both WVTR and OTR measurements no longer depend on the sensor used, but on the sealing of the measuring cell.

In the meantime, the Dresden institute has filed a patent for the new technology. "We expect this method to raise permeation measurement technology to a new level," says Dr. Wulf Grählert, who led the SimPerm project at Fraunhofer IWS. "The advantages are obvious: We can use it to examine the gas permeability of any barrier films for OLEDs, pharmaceutical products or medical technology applications, but also for food, much more realistically and thus more reliably, without having to make any compromises in terms of sample size or examination temperature."

For the first time, laboratories can perform such permeation measurements for typical air components such as water vapor and oxygen in a single operation and with a single instrument, reducing the capital and operating costs of typical gas permeation testing. It also provides information on the breakthrough behavior of the permeates, showing how quickly, or more accurately, how slowly a given amount of water vapor or oxygen permeates through the barrier. Last but not least, the reliable simultaneous analysis of the permeation properties allows conclusions to be drawn about how the different permeates influence each other during the passage through the barrier layers.

Looking further into the future, even more fields of application could open up for the innovative measurement technology. "Cardiac pacemakers and other implants have to be particularly protected against moisture in the body at certain points," explains Grählert. Because the new technology enables reliable, highly sensitive comprehensive permeation analysis even on very small sample areas, this greatly facilitates the development of new barrier films.

As a next step, Dresden-based Sempa Systems GmbH plans to build market-ready measuring systems based on this technology. In addition to Fraunhofer IWS and Sempa Systems GmbH, the Dresden-based CREAVAC GmbH was a partner in the joint project SimPerm, which has now been completed.