This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

proofread

Applying AI to crack the problem of safer, better petroleum processing

A major part of making heavy crude oil into gasoline and other products is the fluidic catalytic cracking processing. The process, first used commercially in 1915, has since undergone a variety of refinements but could be made safer and more effective, according to researchers based in China. The answer? Artificial intelligence.

The researchers published how artificial intelligence could improve the catalytic cracking process, which involves chemically breaking down the long molecules comprising heavy crude oil and separating them out as the desired products on April 7 in Big Data Mining and Analytics.

"Safety, efficiency and environmental protection are the core goals of petroleum processing," said first author Fan Yang, a researcher with the College of Computer Science at Sichuan University. Yang is also affiliated with New Hope Liuhe's Algorithm and Big Data Center. "Abnormal operating condition, early warning, product yield analysis and optimization, and flue gas desulfurization analysis and optimization are the hotspots we're researching to improve safety, efficiency and environmental protection, respectively."

According to Yang and his co-author Mao Xu, a researcher with the New Hope Liuhe's Data Intelligence Lab, advancements in both data acquisition and the artificial intelligence used to understand the data provide the path forward.

"The improvement of industrial data collection technology enables us to obtain more data for analysis," Xu said. "The development of artificial intelligence enables us to analyze these data more accurately."

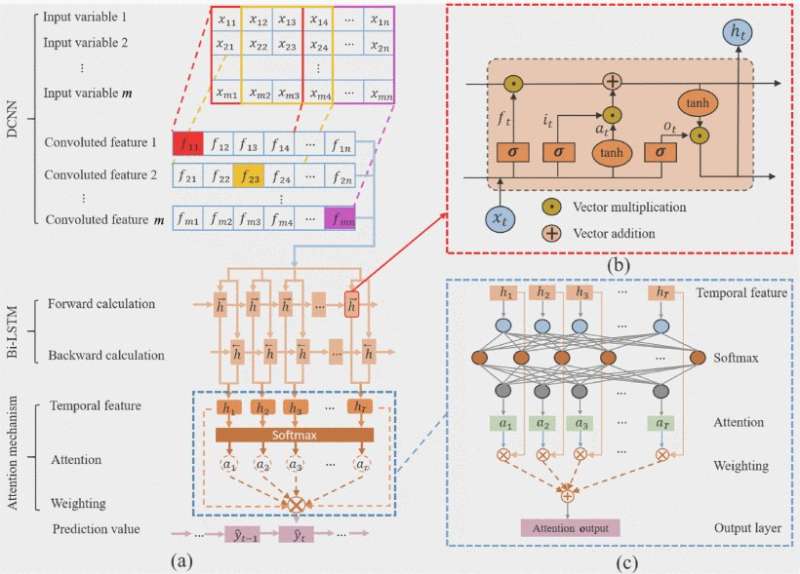

To better examine and optimize the process of catalytic cracking, the team investigated neural networks. This type of artificial intelligence models how it processes data on the human brain, using interconnected nodes to quickly analyze large amounts of data. It learns as it processes, identifying how seemingly disparate data points can signal a larger issue or a potential opportunity when pulled together. Consider temperature, vapor production and yield of desired product.

Neural networks, although based on human brains, are not limited by human focus. They can pull in thousands upon thousands of data points related to those three variables and see how they may influence each other to produce different results.

"This type of machine learning is data driven, and it can solve high-dimensional problems automatically and efficiently," Xu said. "By combining machine learning with a mechanism model—or an algorithm that understands how a mechanism results in a behavior—we can further reduce uncertainties and improve prediction performance."

Xu noted that other machine learning models can be fitted to neural networks, mapping the non-linear relationship of the chemical process in catalytic cracking. In this approach, the researchers can also select for certain features or reduce the number of dimensions considered by the artificial intelligence to investigate more nuanced connections.

"The paper provides a comprehensive review of fluidic catalytic cracking process analysis, mainly introducing methods based on traditional mathematical mechanisms and artificial intelligence," Yang said. "The neural network method shows great advantages as it can effectively deal with the high-dimensional and non-linear characteristics of catalytic cracking processes, obtaining better results in process analysis and optimization research."

The researchers said they plan to eventually test their neural networks, which perform well in simulations, in the actual production process.

"In future research, hybrid models combining mechanism models and artificial intelligence algorithms are expected to become powerful tools for more comprehensive and accurate analysis of chemical processes and prediction of production results," Yang said. "These methods will play an important role in the future development of the chemical industry and will be of great value."

More information: Fan Yang et al, Artificial Intelligence Methods Applied to Catalytic Cracking Processes, Big Data Mining and Analytics (2023). DOI: 10.26599/BDMA.2023.9020002