May 31, 2023 report

This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

A cleaner approach to refrigeration using a squeezable metal

A team of material scientists at the University of Maryland, working with one colleague from Jiaotong University and another from Beihang University, both in China, has developed a cleaner approach to building cooling systems based on the use of a squeezable metal. Their research is published in the journal Science.

Coolant materials used in refrigerators are harmful to the environment, and engineers are searching for a cleaner alternative. One such researcher is Ichiro Takeuchi at the University of Maryland. Over the past decade, he and his team have worked to find a way to use electrocaloric materials as cooling agents.

Such materials undergo temperature changes when stretched or are compressed due to phase transitions. More specifically, he and his colleagues have been working with wires made from nickel and titanium, (NiTi), which have been found to be electrocaloric, to build cooling systems. Multiple engineering challenges stand in the way of building a commercially viable product, but in this new effort, they have overcome several of those challenges.

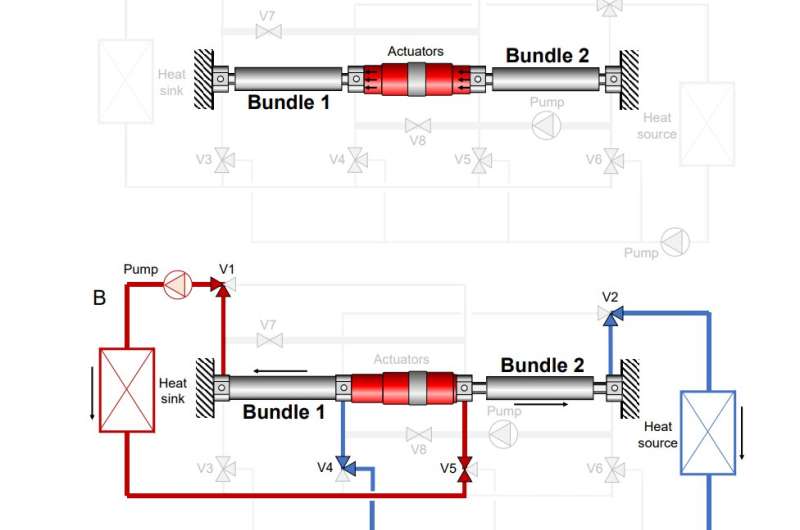

Two of the biggest challenges involve efficient fluid recovery (water is used as the heat exchange) and ways to reduce heat loss that results from friction. Solutions have included using denser bundles of NiTi tubes and an improved actuator, which applies load bundling. Their system uses two bundles connected using the actuator—as the loads are bundled and unbundled, the system moves through cycles of compression on the NiTi, which drives cooling, and thus refrigeration.

The model has two modes, depending on the amount of water in the system—one mode was designed to optimize cooling, and the other temperature span. The system has been shown capable of cooling a system by 22.5K.

The team acknowledges that their system is not yet ready for commercialization, but expect that certain improvements will make it so. They plan to improve its efficiency by improving the actuator and by tinkering with the percentages of nickel and titanium used to make the tubes.

More information: Suxin Qian et al, High-performance multimode elastocaloric cooling system, Science (2023). DOI: 10.1126/science.adg7043

© 2023 Science X Network