This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

proofread

A cellulose-based thickener to reduce environmental risks of liquefied stabilized soil

In many regions across the globe, rapid economic growth has increased the industrial waste generated from construction sites. The environmentally responsible disposal of this waste is a challenge. However, governments are now enacting stricter laws to prevent waste generation and ensure proper disposal of such waste.

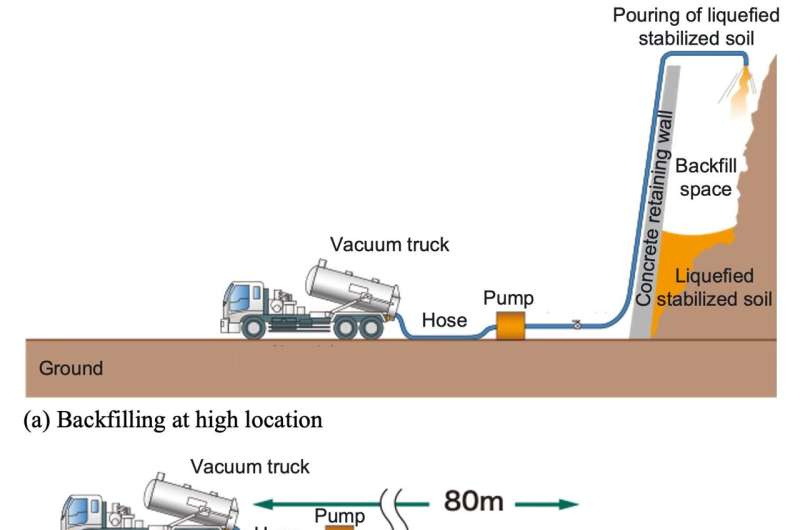

Popularized in the 1990s, liquefied soil stabilization is one approach to reuse excavated soil and harmful sludge at construction sites. The construction-generated waste is mixed with cement or other solidifying materials and reused as backfill for reinforcement and ground stabilization. The ability to pump and pour this material across a site is especially advantageous when applied in areas with constraints related to soil compaction that require rapid solidification.

Unfortunately, liquefied stabilized soil has drawbacks and isn't environmentally friendly. First, "bleeding" can occur—when the water in the stabilized soil rises to the surface, and the denser materials settle to the bottom—which causes a loss in soil strength. Next, it cannot be poured over long distances due to fluidity constraints.

Lastly, the cement solidifiers used during its preparation may contain chromium that can leach into the environment and cause heavy-metal contamination. A team of researchers at Shibaura Institute of Technology (SIT) has recently shown that altering the solidifiers and thickeners can help circumvent the existing structural and environmental limitations of liquefied stabilized soil.

The team was led by Prof. Shinya Inazumi from the School of Engineering and Science at SIT, and their findings were made available online in Case Studies in Construction Materials.

"Construction sludge and excavated soil has traditionally been considered waste, but its disposal bears an environmental cost. We are pursuing creative ways to regenerate this waste so it can serve as an environmentally friendly resource. Our geotechnical advancements have allowed us to tweak the liquefaction and stabilizing parameters to improve the soil's characteristics," says Prof. Inazumi, elaborating on the team's motivation behind the research.

To overcome environmental and structural limitations, the team used a cellulose-based thickener to inhibit the bleeding phenomenon and maintain fluidity. Additionally, ordinary Portland cement (OPC) solidifier was replaced with a mixture of earth silica-blast furnace slag powder (ES-B).

ES-B is more sustainable as it does not contain any chromium, its components can be altered to adjust the rate of curing, and when mixed with soil, it enables homogenous mixing and better fluidity of the end product. While the team studied how a solidifier with more ES-B and less OPC influenced soil characteristics, their main focus was understanding the impact of using a cellulose-based thickener.

The researchers found that strength of the liquefied stabilized soil remained unaffected by the addition of the cellulose-based thickener, and was able to completely suppress bleeding and prevent the separation of soil components, compared to soil that didn't incorporate a thickener.

"While the soil's fluidity did decrease, the cellulose-based thickener did not cause any difference in the reaction products nor resulted in the stabilized soil affecting its surroundings when immersed in water," explained Prof. Inazumi.

These improvements to liquefied stabilized soils offer several advantages, which will help facilitate the environment-friendly disposal of industrial waste, but also improving the stability of building foundations—especially in earthquake-prone zones. The reuse of waste material will also improve the circularity of construction projects, resulting in cost savings and reduced environmental impact. This technology will also reduce the time needed for ground improvement on construction sites, improving operational efficiency.

More information: Yuji Shigematsu et al, Experimental study on properties of liquefied stabilized soil produced with different types of solidifiers and thickeners, Case Studies in Construction Materials (2023). DOI: 10.1016/j.cscm.2023.e02407