This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Novel design method optimizes performance of microelectromechanical system pressure sensor

A research team led by Prof. Wang Junbo from the Aerospace Information Research Institute (AIR) of the Chinese Academy of Sciences (CAS) has introduced a novel simulation-based evolutionary method for the design of parameter-free microelectromechanical system (MEMS) structures, which aims to maximize the degrees of freedom in MEMS design.

The study was published in Microsystems & Nanoengineering on Oct. 25.

The new design methodology enables semi-automatic structure evolution by meticulously assessing the attributes of each segment of the structure. Through a series of iterations, it produces an optimal design that promises significant improvements in MEMS performance.

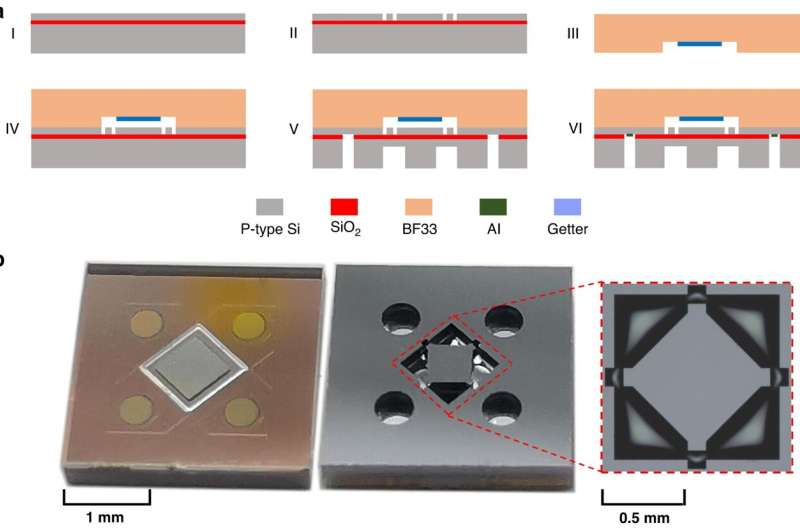

To demonstrate the method's capabilities, the researchers applied it to the optimization of a pressure-sensitive diaphragm used in a piezoresistive pressure sensor (PPS).

Finite element method (FEM) simulations were conducted to evaluate the results. Compared to traditional diaphragms lacking islands and those with square islands, the optimized diaphragm exhibited remarkable enhancements. It increased stress levels by 10% and 16%, while simultaneously reducing nonlinearity by 57% and 77%, respectively.

These improvements underscore the advantages of the newly introduced design method. By tailoring MEMS structures to maximize their performance, researchers can potentially boost a wide range of applications, from medical devices to automotive sensors.

Furthermore, the researchers characterized the fabricated PPS and found that it boasted a high sensitivity of 8.8 mV/V/MPa and a remarkably low nonlinearity of just 0.058% Full Scale (FS) at 20°C.

"This design method makes it possible for the MEMS engineering to create microscale structures with excellent performance and adaptability," said Prof. Wang.

More information: Qinggang Meng et al, A novel evolutionary method for parameter-free MEMS structural design and its application in piezoresistive pressure sensors, Microsystems & Nanoengineering (2023). DOI: 10.1038/s41378-023-00596-y