This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

trusted source

proofread

Researchers find way to weld metal foam without melting its bubbles

Researchers at North Carolina State University have now identified a welding technique that can be used to join composite metal foam (CMF) components together without impairing the properties that make CMF desirable. CMFs hold promise for a wide array of applications because the pockets of air they contain make them light, strong and effective at insulating against high temperatures.

CMFs are foams that consist of hollow, metallic spheres—made of materials such as stainless steel or titanium—embedded in a metallic matrix made of steel, titanium, aluminum or other metallic alloys. The resulting material is both lightweight and remarkably strong, with potential applications ranging from aircraft wings to vehicle armor and body armor.

In addition, CMF is better at insulating against high heat than conventional metals and alloys, such as steel. The combination of weight, strength and thermal insulation means that CMF also holds promise for use in storing and transporting nuclear material, hazardous materials, explosives and other heat-sensitive materials.

However, in order to realize many of these applications, manufacturers would need to weld multiple CMF components together. And that has posed a problem.

"Traditional fusion welding uses a filler to connect two pieces of metal," says Afsaneh Rabiei, professor of mechanical and aerospace engineering at NC State and corresponding author of a paper on the new research published in Advanced Engineering Materials titled "A Study on Welding of Porous Metals and Metallic Foams."

"This is problematic because the metal being melted to fuse two pieces of CMF is solid, so it lacks the desirable properties of the CMF on either side of it. In addition, any type of welding that uses direct heat to melt the metal results in some of the porosity in the CMF being filled in, which impairs its properties. In short, that means that most forms of traditional welding don't work well with metal foams."

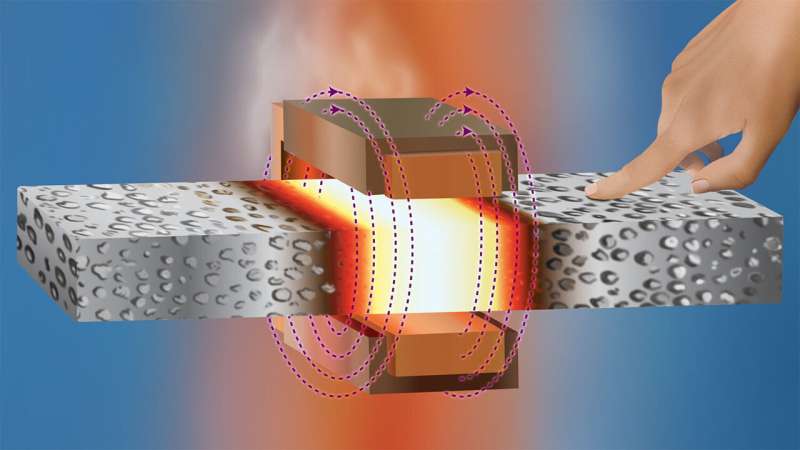

However, the researchers have now identified a form of welding that works very well. It's called induction welding, and it uses an induction coil to create an electromagnetic field that heats the metal for welding.

"Because CMF is only 30%–35% metal, the electromagnetic field is able to penetrate deeply into the material—allowing for a good weld," Rabiei says. "The air pockets that make up the remaining 65%–70% of the CMF serve to insulate the material against the heat. This allows induction welding to heat up the targeted area for joining two pieces of CMF, but prevents the heat from spreading out from the site of the join. That helps to preserve the CMF's properties.

"This is an important step forward, because CMF's properties make it attractive for a wide range of applications, but it's essential to have a means of welding the CMF components without impairing the properties that make it attractive in the first place."

More information: Afsaneh Rabiei et al, A Study on Welding of Porous Metals and Metallic Foams, Advanced Engineering Materials (2023). DOI: 10.1002/adem.202301430