January 9, 2024 feature

This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Light-emitting textiles for diverse flexible and wearable displays

Textile research has highlighted the advances in electroluminescent threads as suitable biomaterials for driving growth in the wearable electronics market. While the direct embroidery of textiles with custom designs and patterns can offer substantial benefits, machine embroidery can challenge the integrity of these threads.

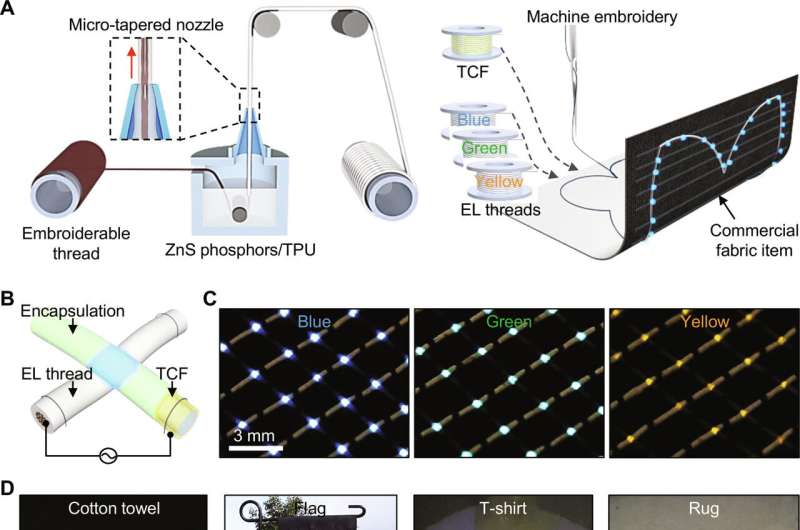

In a new report of applied science and engineering published in Science Advances, Seungse Cho and a team of scientists in biomedical engineering and medicine in the U.S., present embroiderable, multicolor, electroluminescent threads in blue, green, and yellow, that show compatibility with standard embroidery methods.

The researchers used the threads to stitch decorative designs onto a variety of consumer fabrics, without compromising their wearability or light-emitting capacity. The scientists illuminated specific messages or designs on the consumer products for the purpose of developing emergency alerts on helmet liners and as physical hazard signs.

The outcomes deliver a comprehensive toolkit to integrate light-emitting textiles into trendy customized crafts that can even be tailored for leisure wear, with diverse and flexible options.

Light-emitting wearables

Light-emitting textiles have gained increased attention due to their capacity to create dynamic and interactive lighting effects to make them well-suited as wearable fashion in health care and for display purposes. Light-emitting diodes and other light sources such as electroluminescent thin films can be glued directly onto garments of interest. However, such approaches can still affect the inherent properties of the fabric, such as flexibility, wearability, and washability.

Recent advances in electroluminescent threads that can be woven or knitted have facilitated the integration of light-emitting textiles on a large-scale to include vast arrays of lighting lines or pixels. A versatile tool that can include light-emitting textiles into fashionable and customized crafts directly onto consumer fabrics remains to be implemented to suit wide-ranging applications.

While embroidery and machine embroidery aim to deliver fast and precise knitting and weaving for large-scale production. The electroluminescent threads remain to meet the machine embroidery requirements due to their high tensile strength and a smooth surface.

In this work, Cho and team presented embroiderable multicolor electroluminescent threads in blue, green, and yellow, which showed compatibility with universal embroidery machines to stitch decorative designs on a variety of consumer fabrics. These threads were durable against folding, stretching, and machine washes, to satisfy the necessities of machine embroidery. Cho and team presented a range of machine-crafted, light-emitting textiles, for pragmatic applications in display messages and to design functional emergency signals.

Embroiderable multicolor electroluminescent threads

The scientists covered the production of embroiderable multicolor electroluminescent threads with subsequent machine embroidery inserted into the light-emitting textiles. At the onset, they coated the electroluminescent layer with a mixture of zinc sulfide phosphors and thermoplastic polyurethane across the surface of a conductive, embroiderable thread.

They conducted the process using a household manual winder and a tapered nozzle tip to achieve a maximum coating rate. The team applied the electroluminescent layer across the threads and used doped zinc sulfide phosphors with copper and manganese for the blue, green, and yellow light.

The researchers prepared a transparent conductive fiber by coating a transparent, embroiderable nylon fiber with silver nanowires using an adhesion promoter made of ethyl acetate and resorcinol. The team chose silver nanowires for their low electrical resistance, high optical transmittance, and mechanical flexibility.

Physical and optical characterization of electroluminescent threads and light-emitting pixels

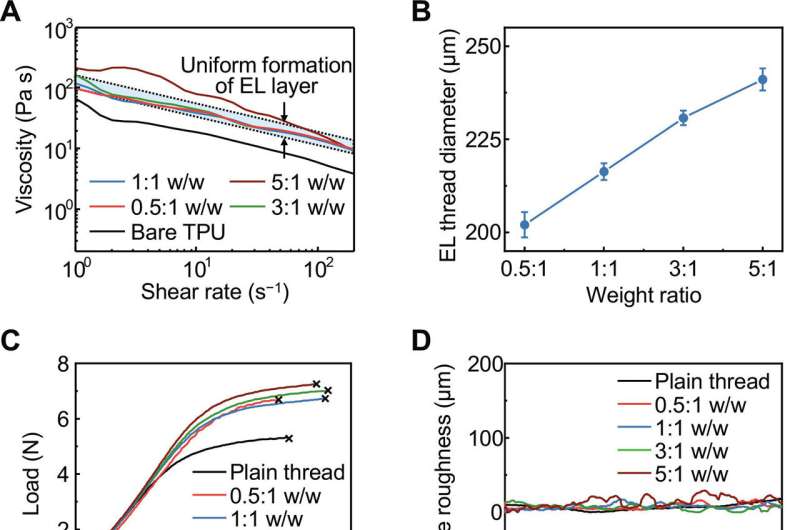

The electroluminescent threads met specific requirements including consistent coverage, a tensile strength of greater than 6 Newton and moderate elongation with a surface finish with minimal roughness. The scientists prepared the electroluminescent layers with different weight ratios of zinc sulfide phosphors and thermoplastic polyurethane.

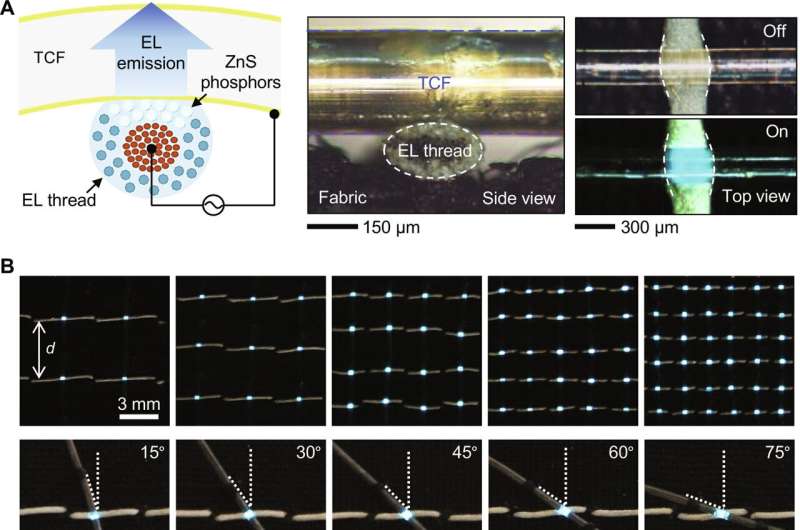

When the shear rate increased, the electroluminescent layers showed shear-thinning behavior as their viscosity decreased. Cho and team noted the overall structure and characterized the light-emitting pixels to present a schematic illustration and a representative microscopic image of a light-emitting pixel that contained an electroluminescent thread at the bottom and a transparent conductive fiber at the top.

The relative change in the electroluminescent intensity of the light-emitting pixels remained constant across these cases. The scientists used a live streaming demonstration to show how the light-emitting pixels on a rug remained intact even after stepping on its surface, to facilitate an on/off switch on the material by an adult with a robust weight.

Light emission characteristics

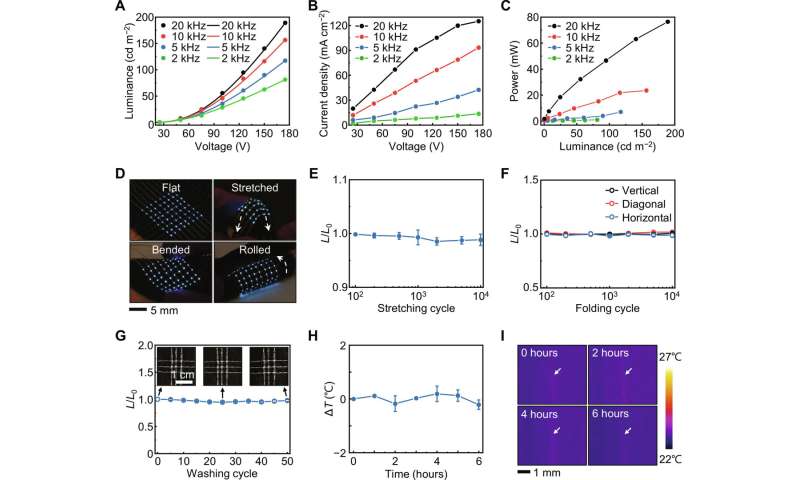

The scientists varied the alternating current voltage to show its influence and frequency on the electroluminescence. The increased frequency at a fixed voltage gradually increased the light-emission intensity to obtain a variable luminance. The scientists conducted multiple laundry cycles on the light-emitting pixels, while also conducting stretching and folding actions.

During the wash, the researchers included a commercial liquid detergent in autosensing mode for 45 minutes in a spin-rinse-and-spin-drying cycle. The light-emitting pixels showed minimal temperature changes for more than six hours during the wash cycle to highlight their suitability for long-term continuous use.

-

Light emission characteristics. (A) Luminance variation of the light-emitting pixels in response to applied voltages at different frequencies (circles) and corresponding fitting curves (lines). (B) Current density of the light-emitting pixels with respect to applied voltages at different frequencies. (C) Power consumption of the light-emitting pixels with respect to luminance at different frequencies. (D) Photographs of light-emitting textiles under stretching, bending, and rolling. (E) Relative EL intensity of the light-emitting pixels during 10,000 stretching cycles at a tensile strain of 20%. Error bars represent SD, n = 3 for each group. (F) Relative EL intensity of the light-emitting pixels during 10,000 cycles of vertical, diagonal, and horizontal folding. Error bars represent SD, n = 3 for each group. (G) Relative EL intensity of the light-emitting pixels during multiple laundry cycles. Insets show photographs of the corresponding light-emitting textile. Error bars represent SD, n = 3 for each group. (H) Local temperature variations of the light-emitting pixels. Error bars represent SD, n = 3 for each group. (I) Thermal images of the light-emitting pixels after continuous operation up to 6 hours. Credit: Science Advances, doi: 10.1126/sciadv.adk4295 -

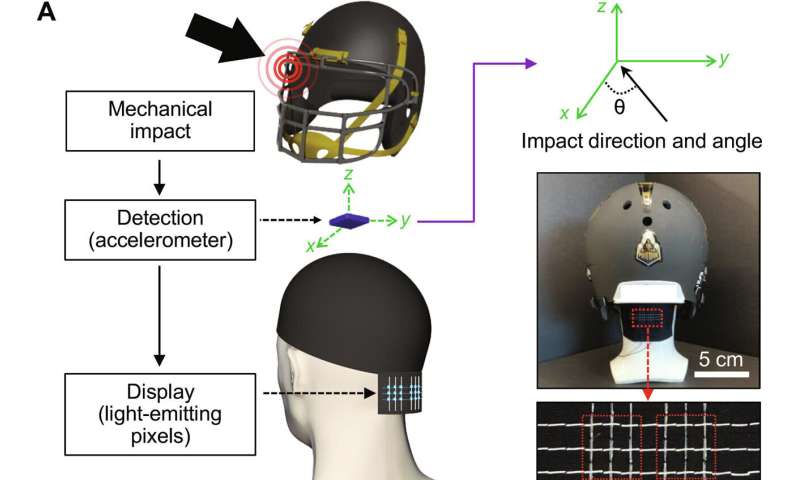

Proof-of-concept demonstrations. (A) Schematic representation of the comprehensive head impact monitoring system, which incorporates a 6 × 3 array of light-emitting pixels into a commercial helmet liner designed for compatibility with a football helmet and includes an integrated impact sensor. (B) Photographs of the illuminated light-emitting pixels following an impact in either the x direction (θ = 0°) or at an oblique angle (θ = 70°) with varying levels of impact severity (mild, moderate, and severe). Credit: Science Advances, doi: 10.1126/sciadv.adk4295

Proof-of-concept

To demonstrate the capacity of wearable displays, the scientists embroidered a 6 x 3 array of light-emitting pixels onto a commercial helmet liner as a football helmet equipped with an impact sensor. They aimed to detect potentially severe head impacts to alert the wearer of a potential concussion, with a real-time warning system. Such wearables can prevent and manage traumatic brain injury prevalent in collision sports, for the early detection and treatment of potential head impacts or concussions.

The measurement setup contained a football helmet equipped with an accelerometer, microcontroller, relay, and power supplier. The construct also maintained a stretchable helmet liner with light emitting pixels, for real-time detection of impact severity.

Cho and team applied mechanical impacts to a mannequin head with a dumbbell and classified the severity as mild, moderate, to severe. The experiments showed how the mechanical impact on the head could be visualized to detect early concussion management in sports or in situations that include the risk of danger in daily life.

Outlook

In this way, Seungse Cho and colleagues present a versatile concept for crafting light-emitting textiles with multicolor electroluminescent threads and transparent conductive fiber that are compatible with standard embroidery machines. These strings were thinner and more durable for machine embroidery with adjustable colors, luminescent intensities, and pixel positions to attain higher versatility and creative potential to meet an array of applications.

The proof-of-concept, light-emitting textiles emphasize the integration of safer power mechanisms, and insulation strategies to ensure the safety and practicality of the wearable electronics.

The team suggests the inclusion of a circuit driver specifically tailored for power supply—to meticulously regulate the voltage, frequency, and waveform. This setup can be used to display real-time measurements of collisions as an ideal solution for health-related applications and to visualize data.

More information: Seungse Cho et al, Machine embroidery of light-emitting textiles with multicolor electroluminescent threads, Science Advances (2024). DOI: 10.1126/sciadv.adk4295

© 2024 Science X Network