This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Pore evolution secrets revealed: New study unlocks additive manufacturing potential

A collaboration between Queen Mary University of London, University College London (UCL), Rolls-Royce, and a team of international researchers has unlocked the secrets of pore evolution in directed energy deposition (DED) additive manufacturing. Their findings, published in Nature Communications, pave the way for safer and more efficient production of high-value components across diverse industries.

DED is a revolutionary technique that builds intricate structures layer-by-layer, ideal for creating complex geometries for products in aerospace, automotive, marine, and even biomedical fields. It also holds immense potential for repairing safety-critical parts, such as damaged jet turbine blades. However, widespread adoption has been hampered by the unpredictable formation of pores during the DED process. These tiny air bubbles weaken components, jeopardizing their performance and raising safety concerns.

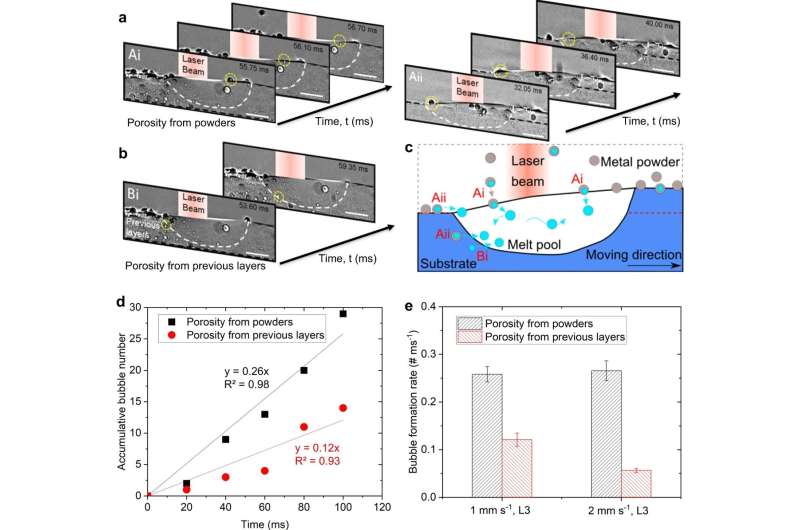

"Until now," explains Dr. Chinnapat Panwisawas, Senior Lecturer in Materials and Solid Mechanics at Queen Mary's School of Engineering and Materials Science, "the exact mechanisms behind pore formation and evolution in DED remained a mystery. Our study sheds light on this critical aspect, revealing five distinct processes that contribute to their behavior: gas bubble migration and coalescence, surface tension effects, and entrapment by solidification fronts."

The researchers employed advanced in situ X-ray imaging and multi-physics modeling to achieve this breakthrough. Their findings provide a detailed understanding of how pores form, move, and interact within the melt pool during DED, enabling the development of targeted strategies to minimize their presence.

"This knowledge is crucial for unlocking the full potential of DED," emphasizes Dr. Panwisawas. "By minimizing porosity, we can improve the mechanical properties of components, making DED a viable option for safety-critical applications ultimately leading to the production of stronger, safer, and more reliable components across various industries."

More information: Kai Zhang et al, Pore evolution mechanisms during directed energy deposition additive manufacturing, Nature Communications (2024). DOI: 10.1038/s41467-024-45913-9