This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

trusted source

proofread

A single-crystal-like mesoporous material for high-performance lithium storage

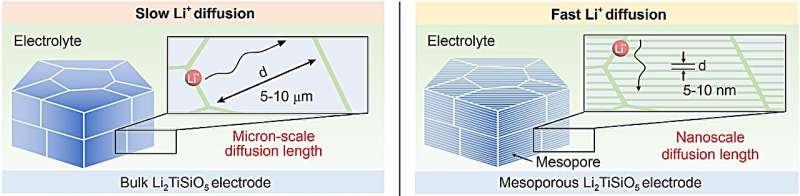

In lithium-ion storage, microstructured single crystal electrode materials show great advantages for ionic conductivity because of removing grain boundaries inside the materials but usually trade off the diffusion distance of Li ions in the microsized particle, consequently reducing the rate capability and cycle stability.

Therefore, it is highly desirable to design and synthesize the mesoporous single-crystal microparticle material for high-performance lithium storage, which combines the microstructure and nanostructure advantages.

Li2TiSiO5, as one of the ternary metal oxides (Li2O-TiO2-SiO2), exhibits a two-electron (Ti4+/Ti2+ redox) conversion reaction between TiO and Li4SiO4 when being used as the anode material for LIBs.

As a result, a high theoretical capacity of 308 mA h g−1 can be obtained.46 More importantly, the Li2TiSiO5 also shows an appropriate and safe working potential at around 0.28 V vs. Li/Li+ which can not only avoid the formation of lithium dendrites but also ensure the high energy density.

However, its low intrinsic electronic and Li+ conductivity of bulk form has frustrated its capacity, cycling, and rate performances. Therefore, it is highly desired but challenging to construct mesoporous Li2TiSiO5 single crystal electrodes with high-rate capability and good cycling stability.

The soft-templating method is the most popular synthesis route to construct highly crystalline and/or single-crystal mesoporous metal oxides. The soft-templating method represents the most straightforward and feasible approach for the synthesis of mesoporous materials due to its simplicity, controllability, and mass production. Many efforts have been devoted to fabricating highly crystalline mesoporous metal oxides through this route.

However, the obtained compositions are usually limited to several single components. In addition, the resultant materials are generally polycrystalline with plentiful grain boundaries and defects, which inevitably lead to negative effects in some application scenarios. Recently, multi-component metal oxides have attracted great interest in various fields. However, to date, there is no report about the synthesis of single-crystal and stoichiometric mesoporous metal oxides with more than three components.

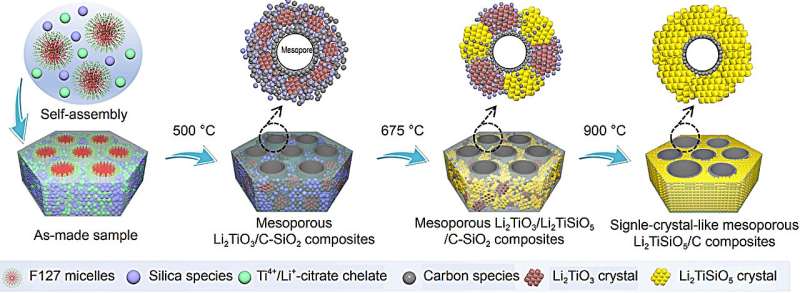

In response to this challenge, recently, for the first time, the team led by Professor Wei Li from Fudan University reported the soft micelle-directed synthesis of single-crystal-like mesoporous Li2TiSiO5 via a step-crystallization strategy. To be specific, stoichiometric chelate precursor (Ti4+/Li+-citrate chelate) is first developed as a lab-made precursor.

Where the abundant carboxyl and hydroxyl groups in the citrate can not only well coordinate Ti4+ and Li+ ions and inhibit the hydrolysis of sensitive titanium and lithium precursors but also enable the successful multi-component co-assembly into ordered mesostructures without phase separation. Subsequently, the interpenetrating carbon and SiO2 matrix are formed via pyrolysis, which works as rigid networks to confine the crystallization of frameworks and protect the mesostructures from collapse.

Interestingly, the amorphous SiO2 can in-situ react with anisotropic Li2TiO3 to form isotropy Li2TiSiO5 single crystal through an oriented attachment crystallization process. Meanwhile, an ultra-thin carbon layer (~2 nm) was coated on the mesopore surface. The obtained single-crystal-like mesoporous Li2TiSiO5 shows a specific surface area (~25 m2 g−1), uniform pore size (~4.0 nm), and single-crystal frameworks .

Notably, the single-crystal-like mesoporous Li2TiSiO5 exhibits a safe working potential (∼0.28 V vs. Li/Li+), maximum lithium storage of 393 mAh g−1 at 0.02 A g−1, superior rate capability (148 mAh g−1 at 5.0 A g−1), and outstanding long-term cycling performance (138 mAh g−1 at 2.0 A g−1 after 3000 cycles) due to fast Li+ diffusion caused by mesochannels, which correspond to nanosized crystal frameworks and short diffusion lengths (5-10 nm).

The findings are published in the journal National Science Review.

More information: Yanhua Wan et al, Micelle-directed self-assembly of single-crystal-like mesoporous stoichiometric oxides for high-performance lithium storage, National Science Review (2024). DOI: 10.1093/nsr/nwae054