March 18, 2024 report

This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Using wood waste products to produce ink for 3D printing of wood objects

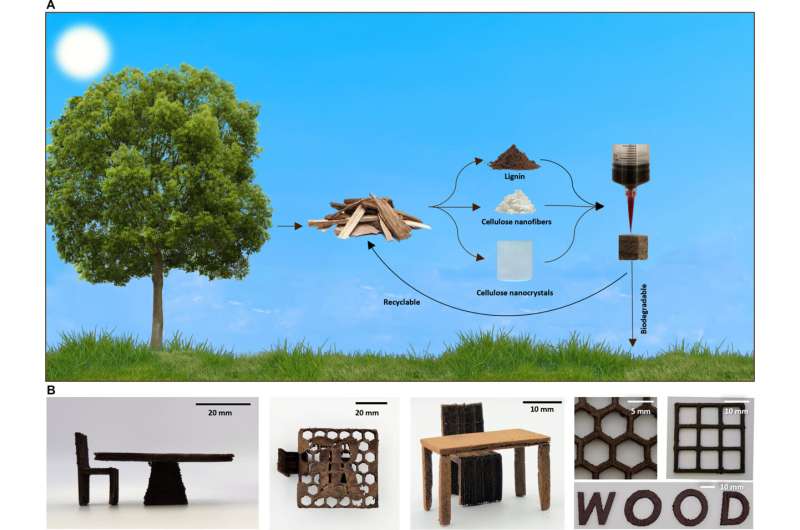

A combined team of materials scientists from Rice University and Oak Ridge National Laboratory has developed a way to convert wood waste into a type of ink that can be used for the 3D printing of wood-like objects. The paper is published in the journal Science Advances.

Using wood to create objects such as tables and chairs is inefficient. After starting with cut boards or chunks of wood, the material is sawed, shaved and/or sanded to craft a desired piece—left behind are many small pieces of wood, along with sawdust. In this new effort, the research team has found a way to use the cast-off material from woodworking to create new objects made of wood.

To make their ink, the research team first chopped up the wood material into a fine dust. They then added chemicals that split the cellulose and lignin apart—both were then broken down further into nanocrystals and nanofibers. Next, the researchers recombined the two and added water, resulting in a clay-like mixture, which they used as ink in a 3D printer.

The team used the ink to create several small-form objects, such as miniature tables and chairs. They then used a freeze-drying technique to remove the moisture from the products and then cooked them at 180°C to fuse the cellulose and lignin. The result was a wood or wood-like object.

The research team found that by manipulating the printing process, they could introduce wood-like textures into the products they made. They also noted that the finished objects also smelled like natural wood.

Testing showed the objects to be up to six times as durable as objects made from original wood, though the researchers only tested balsa. They also found their printed objects were up to three times as flexible as similar objects made with original wood.

Though the process has only been tested with small objects, the researchers suggest that their process could be used for making much larger objects, as well, including real furniture, or perhaps even a house.

More information: Md Shajedul Hoque Thakur et al, Three-dimensional printing of wood, Science Advances (2024). DOI: 10.1126/sciadv.adk3250

© 2024 Science X Network