This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Novel dry-film technique developed for sulfide all-solid-state batteries

The integration of all-solid-state batteries with sulfide electrolytes is emerging as a promising electrochemical system with potential advances in energy density. The demand for thin sulfides, especially those with high flexibility, superior ionic conductivity, and strong interfacial stability, is critical.

The prevailing preference for solvent-free technology is well justified due to its environmental friendliness, cost effectiveness, and suitability for thick electrode production. However, the conventional solvent-free method, which mainly focuses on polytetrafluoroethylene fibrillation, has significant drawbacks such as poor adhesion, insufficient mechanical properties, and susceptibility to electrochemical instability.

Researchers led by Prof. Cui Guanglei from the Qingdao Institute of Bioenergy and Bioprocess Technology of the Chinese Academy of Sciences have developed a novel dry-film technique for the preparation of ultra-thin sulfide solid electrolytes and their integration with thick NCM83 cathodes in all-solid-state batteries through an advanced fusion bonding process.

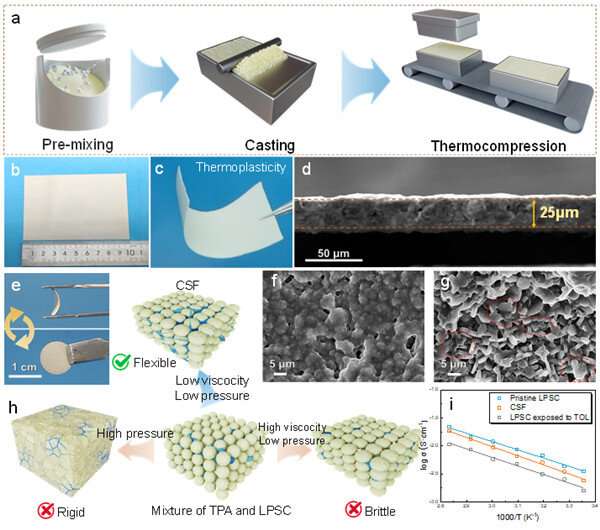

The study, published in Advanced Materials on May 4, demonstrates the successful establishment of a percolation network via a flexible polyamide binder with Li6PS5Cl through thermocompression, facilitating the production of ultrathin films (≤25 μm).

The resulting composite sulfide film exhibits excellent mechanical properties, a remarkable ionic conductivity of 2.1 mS/cm, and a unique stress dissipation mechanism, which is crucial for improving interfacial stability.

Furthermore, the synergistic combination of improved interfaces and stress dissipation has resulted in exceptional cycling performance. This is demonstrated by a capacity retention of exceeding 80% after 707 cycles with a Li–In anode, well beyond the 500 cycles required for practical applications.

In addition, the use of the fusion bonding technology has enabled the fabrication of robust LiNi0.83Co0.11Mn0.06O2 cathodes (~53.1 mg·cm-2) for the construction of integrated all-solid-state batteries. This integration has resulted in a high energy density of 390 Wh·kg-1, nearly 1.5 times higher than that of commercial lithium–ion batteries, and an extended cycle life of more than 10,000 hours.

"Our study underscores the significant practical application potential of fusion bonding technology, with profound implications for the future commercialization of sulfide all-solid-state batteries," said Prof. Cui.

More information: Lei Hu et al, Fusion Bonding Technique for Solvent‐Free Fabrication of All‐Solid‐State Battery with Ultrathin Sulfide Electrolyte, Advanced Materials (2024). DOI: 10.1002/adma.202401909