This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

proofread

Investigating failure mechanisms of solid electrolyte interphase in silicon particles

Lithium-ion batteries are widely used in new energy vehicles due to their low self-discharge rate and long cycle life. Currently, the anode material of commercial lithium-ion batteries mainly adopts graphite, with a theoretical capacity of only 372 mAh g-1—which has gradually failed to meet the increasing demand for energy density.

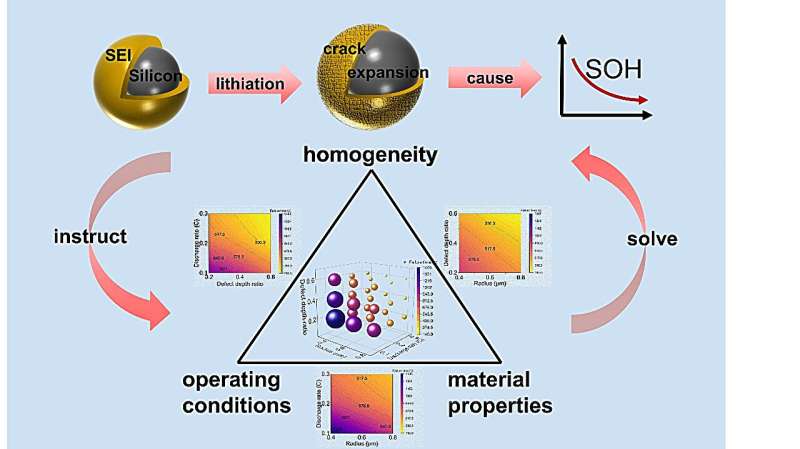

Silicon has been widely studied by virtue of its high theoretical capacity of 4,200 mAh g-1. However, silicon produces volume changes of up to 300% during lithiation and delithiation, and the ensuing mechanical degradation and capacity loss hinder applications.

To reduce the adverse effects caused by mechanical deformation, silicon structure optimization has been intensively investigated and has effectively improved the cycling performance. Nonetheless, the long-term development of silicon-based energy storage materials requires not only stable electrodes, but also a stable interphase between electrodes and electrolytes.

Organic electrolytes, which are widely used in conventional lithium-ion batteries, reduce on the anode surface to form a thin film called solid electrolyte interphase (SEI).

Unfortunately, drastic volume changes in silicon can lead to the accumulation of stress and destruction of the SEI, which will subsequently regenerate on the exposed anode surface, greatly increasing irreversible lithium and electrolyte consumption and causing capacity degradation. Therefore, it is particularly important to stabilize the mechanical properties of SEI on silicon materials.

To that end, the Advanced Power Research Group led by Peng Tan of the University of Science and Technology of China (USTC) has initiated a modeling study on the mechanical stability of SEI from three perspectives: electrode material properties, SEI geometrical properties, and battery operating conditions. The work has been published in Advanced Powder Materials.

The modeling was based on the continuum mechanics model, coupled with the electrochemical mass transfer process.

The team quantitatively analyzed the effects of three factors on SEI stability and battery capacity utilization by building a model of individual electrode particles.

They found out that in order to improve SEI stability, spherical silicons with smaller particle sizes should be used as much as possible in the design of electrode materials. In terms of SEI geometry, it is particularly important to artificially construct SEI with a uniform structure, while when it comes to cell operation, high multiplicity will bring greater capacity utilization but is not conducive to SEI stability.

The findings demonstrate SEI's high-stability design and operation strategy and will guide the development of silicon-based energy storage batteries with high cycling stability.

More information: Junjie Ding et al, Investigating the failure mechanism of solid electrolyte interphase in silicon particles from an electrochemical-mechanical coupling perspective, Advanced Powder Materials (2024). DOI: 10.1016/j.apmate.2024.100200