This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Imperceptible sensors made from 'electronic spider silk' can be printed directly on human skin

Researchers have developed a method to make adaptive and eco-friendly sensors that can be directly and imperceptibly printed onto a wide range of biological surfaces, whether that's a finger or a flower petal.

The method, developed by researchers from the University of Cambridge, takes its inspiration from spider silk, which can conform and stick to a range of surfaces. These "spider silks" also incorporate bioelectronics, so that different sensing capabilities can be added to the "web."

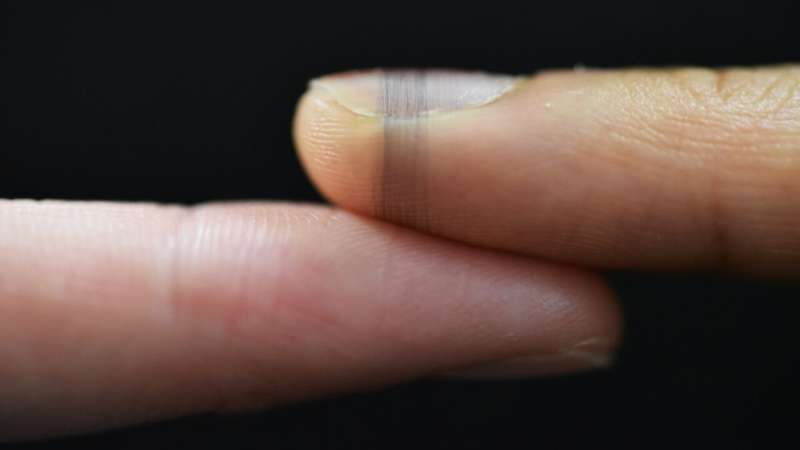

The fibers, at least 50 times smaller than a human hair, are so lightweight that the researchers printed them directly onto the fluffy seedhead of a dandelion without collapsing its structure. When printed on human skin, the fiber sensors conform to the skin and expose the sweat pores, so the wearer doesn't detect their presence. Tests of the fibers printed onto a human finger suggest they could be used as continuous health monitors.

This low-waste and low-emission method for augmenting living structures could be used in a range of fields, from health care and virtual reality, to electronic textiles and environmental monitoring. The results are reported in the journal Nature Electronics.

Although human skin is remarkably sensitive, augmenting it with electronic sensors could fundamentally change how we interact with the world around us. For example, sensors printed directly onto the skin could be used for continuous health monitoring, for understanding skin sensations, or could improve the sensation of reality in gaming or virtual reality applications.

While wearable technologies with embedded sensors, such as smartwatches, are widely available, these devices can be uncomfortable, obtrusive and can inhibit the skin's intrinsic sensations.

"If you want to accurately sense anything on a biological surface like skin or a leaf, the interface between the device and the surface is vital," said Professor Yan Yan Shery Huang from Cambridge's Department of Engineering, who led the research. "We also want bioelectronics that are completely imperceptible to the user, so they don't in any way interfere with how the user interacts with the world, and we want them to be sustainable and low waste."

There are multiple methods for making wearable sensors, but these all have drawbacks. Flexible electronics, for example, are normally printed on plastic films that don't allow gas or moisture to pass through, so it would be like wrapping your skin in plastic film. Other researchers have recently developed flexible electronics that are gas-permeable, like artificial skins, but these still interfere with normal sensation, and rely on energy- and waste-intensive manufacturing techniques.

3D printing is another potential route for bioelectronics since it is less wasteful than other production methods, but leads to thicker devices that can interfere with normal behavior. Spinning electronic fibers results in devices that are imperceptible to the user, but without a high degree of sensitivity or sophistication, and they're difficult to transfer onto the object in question.

Now, the Cambridge-led team has developed a new way of making high-performance bioelectronics that can be customized to a wide range of biological surfaces, from a fingertip to the fluffy seedhead of a dandelion, by printing them directly onto that surface. Their technique takes its inspiration in part from spiders, who create sophisticated and strong web structures adapted to their environment, using minimal material.

The researchers spun their bioelectronic "spider silk" from PEDOT:PSS (a biocompatible conducting polymer), hyaluronic acid and polyethylene oxide. The high-performance fibers were produced from water-based solution at room temperature, which enabled the researchers to control the "spinnability" of the fibers. The researchers then designed an orbital spinning approach to allow the fibers to morph to living surfaces, even down to microstructures such as fingerprints.

Tests of the bioelectronic fibers, on surfaces including human fingers and dandelion seedheads, showed that they provided high-quality sensor performance while remaining imperceptible to the host.

"Our spinning approach allows the bioelectronic fibers to follow the anatomy of different shapes, at both the micro and macro scale, without the need for any image recognition," said Andy Wang, the first author of the paper. "It opens up a whole different angle in terms of how sustainable electronics and sensors can be made. It's a much easier way to produce large area sensors."

Most high-resolution sensors are made in an industrial cleanroom and require toxic chemicals in a multi-step and energy-intensive fabrication process. The Cambridge-developed sensors can be made anywhere and use a tiny fraction of the energy that regular sensors require.

The bioelectronic fibers, which are repairable, can be simply washed away when they have reached the end of their useful lifetime, and generate less than a single milligram of waste. By comparison, a typical single load of laundry produces between 600 and 1,500 milligrams of fiber waste.

"Using our simple fabrication technique, we can put sensors almost anywhere and repair them where and when they need it, without needing a big printing machine or a centralized manufacturing facility," said Huang. "These sensors can be made on demand, right where they're needed, and produce minimal waste and emissions."

The researchers say their devices could be used in applications from health monitoring and virtual reality, to precision agriculture and environmental monitoring. In the future, other functional materials could be incorporated into this fiber printing method, to build integrated fiber sensors for augmenting the living systems with display, computation, and energy conversion functions. The research is being commercialized with the support of Cambridge Enterprise, the University's commercialization arm.

More information: Imperceptible augmentation of living systems with organic bioelectronic fibres, Nature Electronics (2024). DOI: 10.1038/s41928-024-01174-4. www.nature.com/articles/s41928-024-01174-4