This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

trusted source

proofread

Research aims to help improve defect modeling in composite materials

Researchers from the Skoltech Petroleum Center have presented new results that will improve the predictions of stress redistribution used in strength models of composite materials, which will result in fewer tests and costs needed for their production.

The authors upgraded the previously created model by considering the fact that fibers in composite materials can be misaligned, which has a significant effect on modeling predictions. The new paper is published in Composites Part A: Applied Science and Manufacturing.

"Composite materials have been studied for many decades, but despite progress, there is still a large gap between numerical simulations and experimental data. Our goal was to narrow this gap.

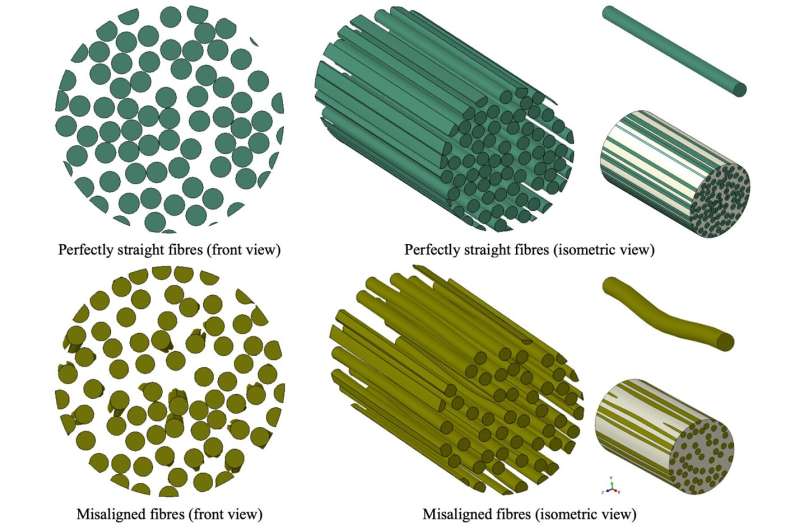

"Composite materials consist of two constituents: fibers and matrix. While fibers in a composite ply show misalignment in reality, they are commonly idealized as perfectly aligned in modeling fiber bundle composites for the sake of simplification.

"In our model, we designed fibers with degrees of misalignment, as they are not perfectly aligned with their direction. This affects the accuracy of calculations and the assessment of the strength models in composite materials," said Milad Jafarypouria, the leading author of the study, a Ph.D. student of the Mathematics and Mechanics program at Skoltech.

The new modeling approach will help to improve the predictions of the fiber-bundle model created in Belgium and applied in the collaborative research published in 2021 to analyze failure mechanisms in polymer composites. These materials find extensive application in industries such as aerospace, where enhancing simulation accuracy to align with experimental data is crucial for reducing the required number of tests and, consequently, cutting down on the costs associated with manufacturing composite structures.

"Engineering has learned how to deal with individual fractures—this area is known as fracture mechanics. During regular inspections, defects are discovered and cut out of the aircraft skin, resulting in a patch being inserted in the area," said co-author Sergey Abaimov, a research scientist at the Skoltech Petroleum Center.

"But there are more dangerous cases—the so-called damage mechanics, when a huge number of microdefects appear in the material that cannot be seen with the naked eye, and we can't send huge aircraft for X-rays.

"Since the material can be oversaturated with such cracks, this can lead to disaster: no one can notice the crack, the plane continues to fly, and then, out of the blue, one of the structural elements collapses. Safety measures are also taken against such situations to duplicate the functions performed by the structural elements, but the question of predicting such types of destruction remains open."

According to the researchers, initially, the model did not take into account a number of aspects, including the fact that all fibers are not perfectly straight.

"The new and subsequent research will help make this model more realistic," continued Abaimov. "Our achievement is that for the first time we were able to simulate the damage in a fiber bundle with a realistic fiber orientation. With the model, we can improve the damage predictions in composite materials to decrease the gap between the simulations and experimental data."

More information: M. Jafarypouria et al, The effect of fibre misalignment in an impregnated fibre bundle on stress concentrations, Composites Part A: Applied Science and Manufacturing (2024). DOI: 10.1016/j.compositesa.2023.108001