This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

A green steel pathway would turbocharge Ukraine's post-war recovery, study finds

As the international community gathers to discuss Ukraine's post-war recovery, a new analysis led by the University of Oxford demonstrates that green steel should be top of the agenda.

Rebuilding Ukraine's ravaged steel sector—once hostilities cease—presents a golden opportunity to harness the striking economic benefits of low emissions steel production, according to researchers at the University of Oxford.

In a new report, "Techno-economic optimization of steel supply chains in the clean energy transition: A case study of post-war Ukraine," published in the Journal of Cleaner Production, they demonstrate that rebuilding Ukraine's steel sector to have near zero emissions would generate $164 billion worth of additional GVA compared to a pathway based on traditional coal-based steelmaking.

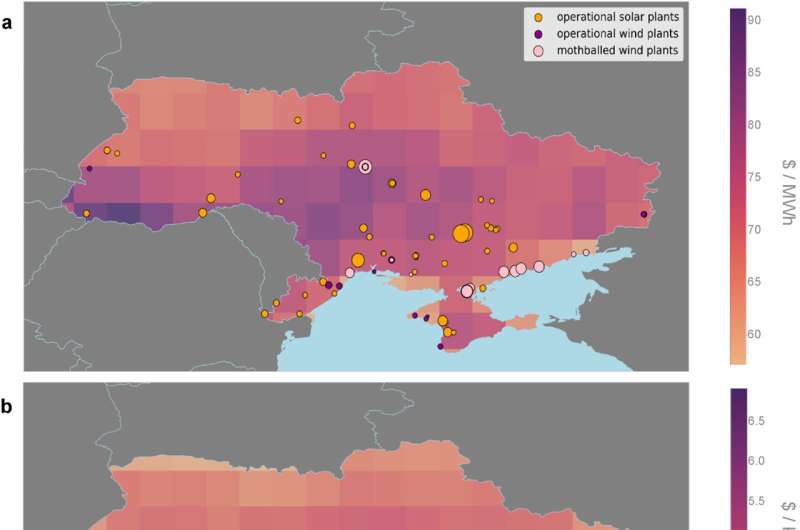

Furthermore, a robust green steel sector in Ukraine would have ripple effects across the entire economy, for instance through stronger supply chain links. For instance, replacing coal as the main heating source in steel furnaces with renewable energy would radically shift the center of gravity of Ukraine's steel industry from eastern regions towards western and southern regions, and accelerate economic growth.

Steel is a significant component of Ukraine's economy. Before the war, Ukraine was the 14th largest global steel producer with 21.4 million metric tons of crude steel output in 2021. But its pre-war steel industry was also one of the dirtiest in the world. In 2020, the Ukrainian steel industry was responsible for 48 Mt CO2: 15% of the country's entire CO2 emissions. If Ukraine were to join the EU, however, it would become subject to "The EU Green Deal" target for near zero-emission steel by 2030.

In the new study, the researchers note that Ukraine has the clear potential to develop the clean energy infrastructure needed for a full green steel transition– including a robust supply of renewable energy, and green hydrogen produced using renewable energy.

Ukraine also sits on vast reserves of iron ore—the main raw material needed to make steel using virgin materials—and is well located for access to European customers.

But successfully redeveloping Ukraine's steel sector will require access to capital, clear climate policies, and strong regional trade links.

The researchers propose that new green steel mills would be situated in close proximity to westward cross-border railway crossings and southbound Black Sea ports, besides optimal solar and wind energy sources.

This would significantly increase demand for land and sea transport services, re-routing them towards Western/EU markets, and also create new demand for the production of green hydrogen and green ammonia for fossil-free fuels.

According to the report, a full steel production recovery in Ukraine would require investment of $62 billion over 20 years: $45.9 billion for renewable energy infrastructure, $6.6 billion for energy storage, and $9.5 billion for iron and steelmaking furnaces. However, this investment would have wider effects: in 2021, for every $1 invested in Ukraine's basic metals industry, an additional $3.28 was generated elsewhere in the economy.

The World Bank estimates that Ukraine's full post-war recovery and reconstruction needs will require $486 billion. Thus, by comparison, Ukraine's green steel investment needs amount to 6% of the country's total post-war reconstruction needs over the first 10-year period.

As a positive step forward, a recent commitment by domestic players (including large Ukrainian steelmakers Metinvest and ArcelorMittal) of $35bn into the medium-term green steel transition strategy until 2035 means the outstanding amount needed would be significantly lower (Metinvest, 2023).

Ultimately, Ukraine could provide an ideal blueprint for an urgently-needed global transition towards low-emission steel production. Globally, steelmaking produces more CO2 than any other manufacturing and construction industry, comprising around 8% of total global emissions—2.8 gigatons of CO2 per year. In comparison, international aviation transport accounts for 2.5% of global CO2 emissions.

With prospective international donors and private investors gathering in Berlin on 11–12 June for the Ukraine Recovery Conference 2024—a high-level annual political event that aims to mobilize international support for Ukraine- the researchers hope that green steel will be high on the agenda.

More information: Alexandra Devlin et al, Techno-economic optimisation of steel supply chains in the clean energy transition: a case study of post-war Ukraine, Journal of Cleaner Production (2024). DOI: 10.1016/j.jclepro.2024.142675