This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

proofread

Researchers develop permeable carbon fiber based thermoelectric film with improved EMI shielding

Thermoelectric technology, which enables the direct conversion of heat into electricity, has emerged as a promising alternative energy source. Notably, this technology can efficiently convert body heat into electrical energy, garnering significant attention in the field of wearable electronics.

However, the dense structure of most thermoelectric materials results in ultra-low moisture permeability. In practical applications, insufficient moisture permeability can trap heat and humidity, fostering bacterial growth and potentially causing skin lesions. Hence, developing thermoelectric materials with superior moisture permeability is crucial.

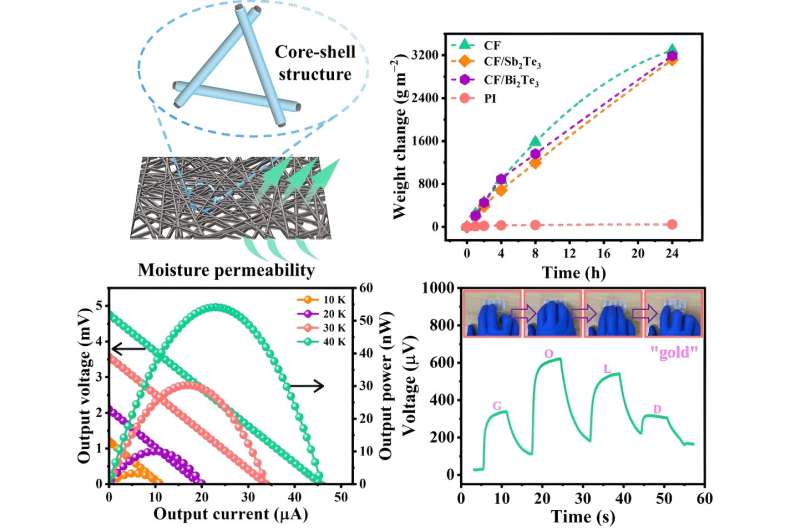

A team led by Peng-an Zong from the School of Materials Science and Engineering at Nanjing Tech University in China recently developed CF/Sb2Te3 (CF/Bi2Te3) films with exceptional thermoelectric properties and moisture permeability. The cross-linked core-shell structure of carbon fiber internals, achieved through electrodeposition, enhanced electrical conductivity.

Additionally, the electromagnetic interference shielding effectiveness (EMI SE) of the composite film was significantly improved. The films were then utilized in sensors, demonstrating effective touch and breathing sensing capabilities.

The team published their study in Journal of Advanced Ceramics on June 5, 2024.

The researchers used carbon fiber (CF) as the substrate material and employed electrodeposition to grow Sb2Te3 and Bi2Te3 on the CF. They studied the films' performance by varying deposition coulombs, deposition potential, and other parameters. The increased internal fiber diameter facilitated carrier movement, significantly enhancing electrical conductivity and thermoelectric performance. As a result, the power factor of the composite film was 300 times higher than that of the CF substrate.

After the electrodeposition of thermoelectric materials, the significant increase in fiber column diameter reduces the surrounding pore size, resulting in a moisture permeability 5% lower than that of CF, but still exceeding 3000 g m−2 day−1. Due to various mechanisms, the EMI shielding effectiveness (EMI SE) of the composite film can reach up to 93 dB.

After electrodeposition of thermoelectric materials, due to the significant increase in the diameter of the fiber column, the surrounding pores are reduced, and the moisture permeability is only 5% lower than that of CF, which over 3000 g m−2 day−1. Owing to the internal fiber structure, the EMI SE of the composite film can reach up to 93 dB.

In addition, the researchers selected the composite films with the best performance for integration of the sensor, which was utilized in touch sensing and respiratory sensing applications. The practical application scenarios of the sensor were demonstrated, and its cycle performance was tested, confirming that the sensor exhibits excellent stability.

More information: Junjie Zhu et al, Permeable carbon fiber based thermoelectric film with exceptional EMI shielding performance and sensor capabilities, Journal of Advanced Ceramics (2024). DOI: 10.26599/JAC.2024.9220922