This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Augmented reality tech aids manufacturing productivity

High-tech factory workers of the future will rely on training and support from Industry 4.0 technology, such as augmented reality head-mounted display modules (AR-HMD), to manage workflow and remote trouble-shooting—including in the next generation of shipbuilders, say Flinders University experts.

Trials of such AR-HMD technologies to improve productivity by reducing and correcting errors in advanced manufacturing and assembly will improve software, tracking and other promising features of such devices, according to a new article published in the journal Ergonomics.

"Despite Industry 4.0 technology adoption being promoted to stimulate manufacturing flexibility and competitiveness, Australia has been slow to adopt it," says first author Dr. Valerie O'Keeffe, a Senior Researcher in Human Factors at Flinders University.

"The Australian Navy Hunter Class Frigate Program provides an opportunity for accelerating technology adoption to improve productivity and workforce skills in a traditional, complex and vital industry.

"Augmented reality head-mounted displays provide digital information directly to the user and can be used to guide completion of work tasks."

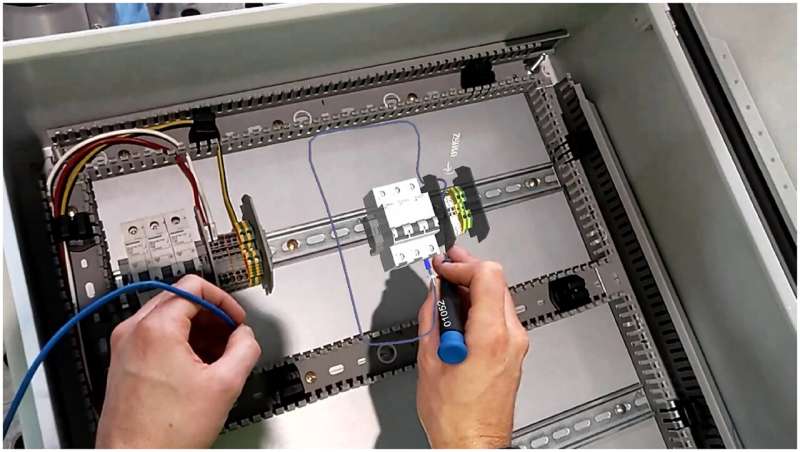

To understand shipbuilders' user experience and workload, the research case study focused on the "AR-HMD Hololens 2" in a simulated manufacturing workflow. This involved multiple tasks (electrical assembly, inspection and quality assurance) with a collaborative robot fitted with a visual inspection camera.

The study took place at the Osborne Naval Shipyard with the support of industry partner BAE Systems Maritime Australia.

Dr. O'Keeffe says the study highlights AR-HMD as a potential vehicle for integrating advanced technologies, improving functionality while minimizing end-user burden.

"This is valuable for fast-tracking learning and building skill levels in a workforce experiencing skilled labor shortages," she says.

"Interface design, tracking, gesturing and device durability were most likely to limit AR-HMD adoption and require improvement to ensure efficient uptake in operations.

"However, our findings suggest encouraging levels of technology acceptance and motivation in the workforce, with potential to promote learning and productivity.

"Findings can inform technology adoption, and translating knowledge to heavy industries beyond shipbuilding."

More information: Valerie O'Keeffe et al, Forming a view: a human factors case study of augmented reality collaboration in assembly, Ergonomics (2024). DOI: 10.1080/00140139.2024.2352733