3D insights into an innovative manufacturing process

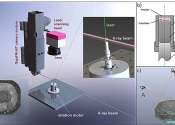

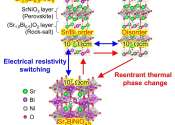

3D printing can produce highly complex shapes. But printing ceramic objects with the help of a laser is a more difficult challenge. Now researchers at the Paul Scherrer Institute PSI have for the first time taken tomograms ...

Sep 19, 2023

0

43