May 26, 2017 report

Running a power plant on carbon dioxide instead of steam

(Tech Xplore)—A team with NET Power is currently in the process of building a power plant in Texas that will use a form of carbon dioxide to turn turbines instead of using steam to make electricity. The plant will be the first in the world to attempt to utilize the new technology. Levi Irwin and Yann Le Moullec with SETA, ManTech SRS Technologies, Inc., and Électricité de France, China Holding R&D respectively offer a Perspective piece on the work being done by the company in the journal Science.

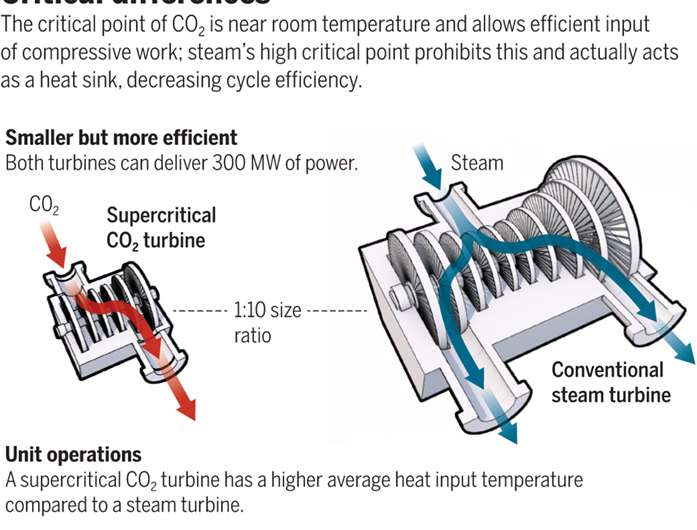

To make large quantities of electricity, huge turbines are powered by the steam produced from boiling water. Despite being inefficient, this process is the worldwide standard—the only variable is the means by which the water is boiled—by burning coal or natural gas, or splitting atoms. But now the standard may change as the team at NET Power is building a plant that replaces steam with carbon dioxide that has been heated and pressurized to induce a supercritical state in which it has the density of a liquid but still expands to fill a space like a gas. Because the gas is much denser, the CO2 approach can use much smaller turbines, increasing efficiency.

But as Irwin and Moullec note, it is not easy to make such a turbine, which is why no one has tried it before, despite the technique's promise. Pressurizing CO2 to the degree needed presents challenges and requires a lot of energy. Also, temperature and pressure have to be controlled precisely, or the CO2 will condense into droplets, causing problems. Also, a turbine had to be modified to work with the supercritical CO2.

In the new plant, natural gas is burned inside an environment of pure oxygen to prevent the release of anything but pure CO2—any excess can be buried or sold, which means that other than water, the plant will be completely emission free. The new facility, which will start operating later this year, is a test site, but the company already has plans to build a much larger plant that will power 200,000 homes. They also believe they can produce electricity at a cost very nearly equal to a natural gas plant.

More information: Levi Irwin et al. Turbines can use COto cut CO, Science (2017). DOI: 10.1126/science.aam8281

Summary

Two-thirds of the electricity in the United States is generated from fossil fuel via combustion-powered steam turbines. To get to the high temperatures needed for high efficiency, steam must first be vaporized from liquid water. The steam is further heated, expanded through the turbine, and condensed to water on the other side. In this process, called the Rankine cycle, the vaporization step is a phase change that requires a large heat input but delivers no increase in temperature (or efficiency). Advanced steam turbines try to avoid the phase change by going to supercritical conditions, but attempts to exhaust heat at low temperatures push parts of this cycle to operate just above water's critical point (374°C and 218 atm). Near this point, steam's heat capacity increases sharply, so up to 36% of total heat input still goes to a low-temperature, vaporizer-like process (see the figure). By switching from steam to supercritical CO2 (scCO2) and running a Brayton cycle (the same cycle run by natural gas turbines), the "vaporizer" step can be avoided, providing an opportunity to replace subcritical steam plants with a cycle that could be up to 30% more efficient. These gains are expected to persist in the smaller turbine sizes suited for harvesting solar thermal energy.

© 2017 Tech Xplore