September 22, 2017 report

'Lego-electronics' offer simple way to assemble integrated circuits

(Tech Xplore)—One of the biggest challenges in the drive to miniaturize electronic devices is the difficulty in aligning and assembling the increasingly tiny electronic components with the necessary precision, which is challenging even for robots. In a new study, researchers have developed a method for converting integrated circuits into "Lego-electronics," whose simple lock-and-key design could ease the manufacturing process, enhance the production rate, and reduce the failure rate of the micro-scale interconnects.

To demonstrate the simplicity of assembling the Lego-electronics, the researchers have shown that the Lego-modules can not only be assembled by robots, but also by a blindfolded person, suggesting that the technology could open up work opportunities in the electronics industry for individuals who are visually impaired.

The researchers, led by Muhammad M. Hussain at the King Abdullah University of Science and Technology (KAUST) in Saudi Arabia, demonstrate the Lego-electronics in an upcoming issue of Advanced Materials Technologies.

"The demonstration decisively increases throughput and yield in CMOS manufacturing systems, especially the emerging area of flexible electronic system production," Hussain said. "By providing geometrical identities to modules, we have demonstrated that a blind person can also assemble it, which may lead to the disruption in employment of blind personnel in the manufacturing and fabrication industry—traditionally believed to have no room for blind individuals."

As the researchers explain, most conventional integrated circuits all have the same geometry and are connected by large numbers of tiny pins on the sides of the devices, which require very precise alignment in order to fit together properly. However, this alignment is a complex process, and even a single interconnect failure may result in overall system failure.

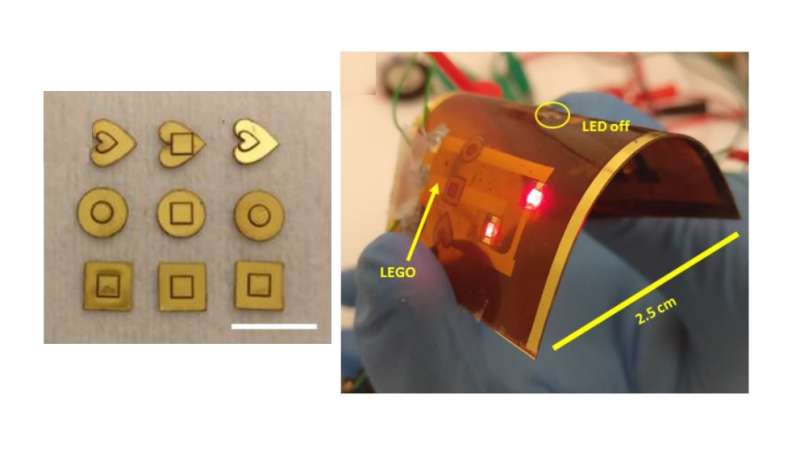

By comparison, the new Lego-electronics have two-layer geometrical shape recognition: the integrated circuits themselves have a unique shape to allow for quick identification, and the devices also have different teeth designs so that they bind only with complementary host sites. Here the researchers demonstrated the lock-and-key concept with hearts, circles, and squares, for devices with dimensions of 3 mm x 3 mm x 0.25 mm, which is the approximate size of a typical integrated circuit.

In experiments with early prototypes, the researchers found that it was necessary to apply light pressure to the Lego-modules in order to ensure that the connection was tight enough to light up an LED, or otherwise apply a microdrop of epoxy at the binding site to ensure the connection.

The researchers also showed that the Lego-electronics can be assembled either by hand or by a robotic pick-and-place tool. To demonstrate robotic assembly, the researchers programmed the robot to identify the component geometries and teeth shapes of the Lego-modules. The robot then achieved a 100% success rate of Lego-module placement, both with and without the epoxy.

Further, the researchers showed that the Lego-modules also have the potential for flexibility when fabricated on flexible substrates. The researchers showed that the devices can undergo extreme bending and retain their functionality when epoxy was used.

While the Lego-modules can be fabricated as original components, the researchers also demonstrated a method for converting existing integrated circuits into Lego-modules. This process involves laser etching a specific pattern on the back of the integrated circuits, creating Lego teeth.

The researchers expect that the Lego-module concept has the potential for widespread adoption, and could one day be used to assemble everything from wearable electronics, flexible displays, health monitoring systems, electronic paper, and an endless variety of sensors that are predicted to play a prominent role in the "internet of everything."

In the future, the researchers plan to investigate how the Lego-modules can be self-assembled.

"The next stage can be to demonstrate the self-assembly process of these modular components," Hussain said. "Guiding the modules to their binding sites using fluidic agitation or surface-tension-driven self-assembly may eliminate the necessity of manual handling of individual modules as well increase the throughput."

More information: Sohail F. Shaikh, Mohamed T. Ghoneim, Rabab R. Bahabry, Sherjeel M. Khan, and Muhammad M. Hussain. "Modular Lego-electronics." Advanced Materials Technologies. To be published.

© 2017 Tech Xplore