July 16, 2018 weblog

Norwegian researchers hit silicon jackpot for top battery solution

Steve Hanley certainly wrote what we are all thinking—groan, not another story about a battery "breakthrough." So many blares from a trumpet begin to fall on deaf ears, but the bleats go on. So what and who are we to take very seriously?

Well, we need to continue paying attention to claims because battery research is ongoing and scientists want better solutions. "CleanTechnica readers sometimes tire of all the stories about new breakthroughs in battery technology—it seems like there is at least one every week—but that is only because there is so much news to report about," Hanley said.

Hanley remarked that "you can almost feel the pace of development in battery technology accelerating day by day if not moment by moment."

On to the latest buzz in batteries. Has a corner been reached and turned? Can we consider a jackpot hit in a way to stabilize silicon anodes for Li-ion batteries? As the news stories go, battery researchers at the Department of Energy Technology (IFE) have solved a challenge facing scientists worldwide .

IFE's battery researchers in Norway are talking in terms of revolutionized range and lifespan as they announce that a way has been achieved to put in silicon as a replacement for the graphite used in anodes of lithium ion batteries. The group thinks they found the X factor regarding batteries.

They are boasting over a solution that allows for far better batteries with higher capacity. Numbers? Business Insider Nordic said the Norwegian researchers found a way to improve the capacity of conventional batteries by 300-500%.

Hanley clarified what the technical hurdle which they knocked down.

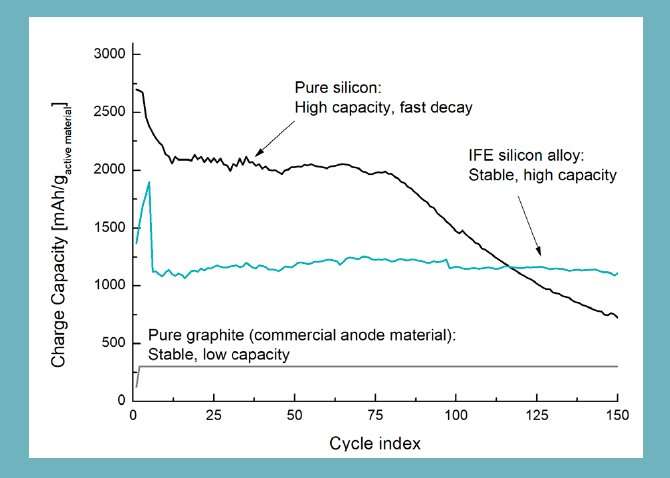

"Pure silicon has ten times more capacity than graphite but it loses capacity faster than graphite. The researchers have found a way to mix silicon with other elements to create an anode that is stable and long lasting and which has three to five times higher capacity than a conventional graphite anode."

Research director Arve Holt. who earned a PhD from the University of Oslo, built up the institute's solar cell processing laboratory and the solar cell characterization laboratory. His specialty is significant as related to the battery research. Holt and colleagues underwent several years of targeted research and experimental trials with nanoparticles, including silicon, in IFE's laboratories, at Kjeller in Norway.

The IEF reports that "research results show that with the new IFE-developed technology, it can achieve three to five times the charge capacity of the negative electrode (anode) as with today's common graphite technology."

Are you thinking what this means in terms of your daily life?

Think about mobile phones that do not need to be charged for days or think about range vis a vis electric cars. Hanley reported that one of the claims for this discovery is that it will lead to batteries that can power an electric car for 600 miles or more.

Business Insider Nordic reminded readers of the potential impact, too, on medical implants, gadgets, appliances and machines using lithium ion batteries.

All in all, said Business Insider Nordic, "Ramping up from lab testing to an industrial setting hopefully means electric cars, smartphones and implants will soon get an enormous performance boost soon."

What's next? IFE said it is ready to take the research into the marketplace. IFE is working on patenting the technology.

"The Institute will work in parallel with several Norwegian and international companies to test the new battery.

The Department of Energy Technology (IFE) is an independent research foundation; one of its better known tasks is managing the Halden Project, which is OECD's largest and longest collaborative project on reactor safety.

© 2018 Tech Xplore