Eco-friendly coal-fired technology for stackless power plants without emissions

Coal-fired power plants in Korea are one of the main sources of air pollutants, CO2 and the other precursor materials to ultra-fine dust particulates such as nitrogen oxide and sulfur oxide. Therefore, FEPCRC is developing key technologies for eco-friendly coal-fired stackless power generation without emissions in flue gas.

The FEP Convergence Research Center (FEPCRC) led by Director Lee Jae-goo at the Korea Institute of Energy Research has successfully developed oxy-circulating fluidized bed combustion (Oxy-CFBC) technology that reduces air pollution by over 80% and separates over 90% of CO2 emissions compared to existing power plant technology with air mode combustion.

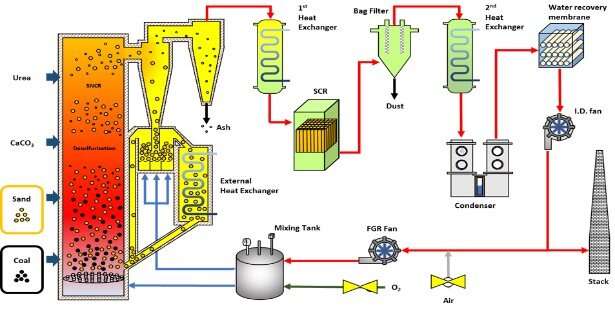

Oxy-CFBC is a promising and advanced combustion technology that makes it possible to separate CO2 efficiently, utilize low grade fuels and remove SOx and NOx by oxy-combustion process combined with CFBC technology.

This process operates below 950 degrees C and does not produce thermal NOx compared to other types of thermal power generation that require a high operating temperature. In addition, it removes NOx and SOx by injecting reducing agents such as urea/ammonia solutions and limestone particles inside combustor. As a result, the difficulty of installing a flue gas treatment system is reduced.

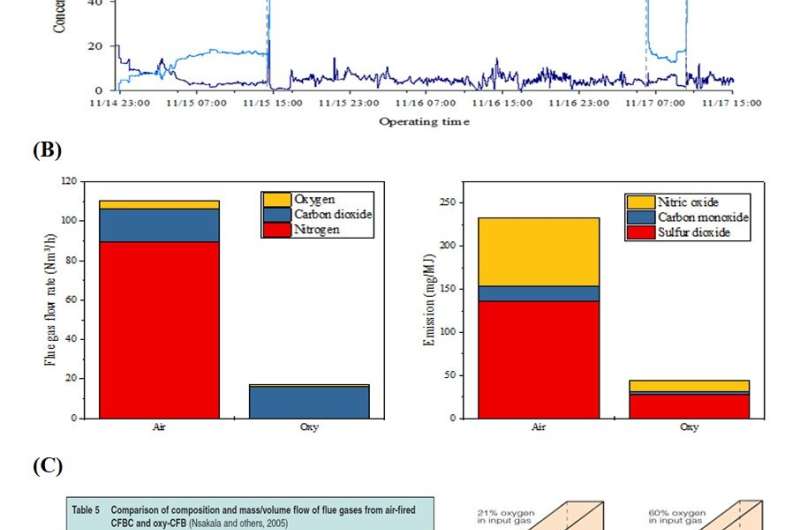

The Oxy-CFBC uses oxygen mixed with recirculating CO2 instead of air as an oxidant and requires only am air separation unit and a flue gas recirculation system, so it is easier to obtain highly concentrated CO2 compared to other carbon-capture technologies. Moreover, this process reduces air pollutants that generate ultra-fine dust as well as the amount of flue gas by about 80% compared to air mode combustion. The Oxy-CFBC process is one of the most advanced technologies that can be operated at 60% of O2 as an oxidant for oxy-combustion.

The higher oxygen concentration for Oxy-CFBC technology plays a critical role in improving the system's efficiency. Current technology uses oxygen concentrations at the level of 40%, but if oxygen concentration increases over 60%, the size of CFBC and downstream facilities can be reduced significantly, resulting in the reduction of capital cost and operating expenses.

The Oxy-CFBC test rig demonstrated that thermal input increases from 100 kWth to 200 kWth when oxygen concentration increases from 21% to 60%. This means that thermal power can be doubled in constant plant size or the plant size can be reduced for constant thermal power.

FEPCRC also developed stable oxidant-switching technology from air-mode combustion to oxy-mode combustion or vice versa, and could obtain a CO2 concentration over 90% within one hour after oxidant switching from air to oxy mode.

Dr. Mun of FEPCRC, who participated in this R&D, said, "It is urgent to develop breakthrough technologies for CO2 and fine dust reduction. Our research team will continue to develop basic design, engineering and operating techniques related to the Oxy-CFBC process with our own technologies, contributing to advanced power generation technology that can separate CO2 during combustion process."

More information: Hoang Khoi Nguyen et al, Oxy-combustion characteristics as a function of oxygen concentration and biomass co-firing ratio in a 0.1 MWth circulating fluidized bed combustion test-rig, Energy (2020). DOI: 10.1016/j.energy.2020.117020