Talc improves pipe performance in geothermal heat pump systems

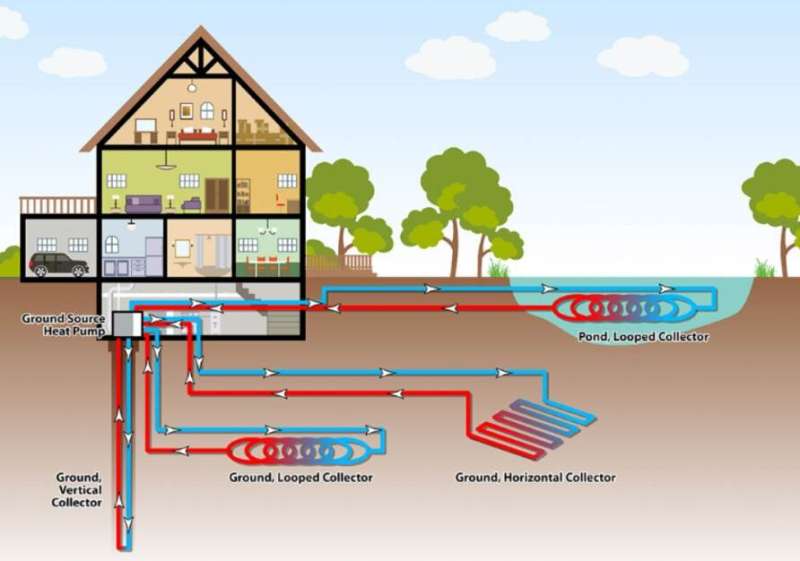

Geothermal energy is an energy source of increasing importance. In the pursuit of energy efficiency to achieve set climate goals, it is important to get to understand the technical challenges in detail. The plastic pipes used in geothermal heating systems are the subject of a research project at the University of Borås, Sweden.

In this project, doctoral student Adib Kalantar Mehrjerdi has investigated how to improve the performance of geothermal heat pump systems by increasing thermal conductivity in the plastic pipes using various additives to the plastic. Common talc mixed into the plastic proved to be a possible solution.

"In fact, we live right on top of the most affordable, sustainable, and comfortable energy source on Earth," Adib Kalantar Mehrjerdi says. "It is an important energy source that could be used to a much greater extent than is done today. It is an energy source that exists anywhere you need it and it is available all the time, unlike sun, wind, which depend on weather and positioning on the Earth, and biomass that must be transported. It also can be scaled up in different sizes from small family houses to big commercial buildings or even mega cities," he continues.

Just few meters below to the ground surface, the temperature is constant all year around; this applies throughout the world. In the summer, the ambient temperature is higher than in the ground and in winter it is vice versa.

"The earth could thus function as a huge thermal battery for free. In the winter, we can extract energy and in the summer, we can store energy in the same system, and then distribute it in the form of heating or cooling," he explains.

Low thermal conductivity a disadvantage

The pipes that are used in heat systems using geothermal energy consist of the polymer material polyethylene. Polymers are considered heat insulating, but in many applications, heat exchange is desired. The pipes used today have many advantages when it comes to processing and production, and they can withstand corrosion and chemicals. The material is also cost effective, and the pipes can easily be transported in a coil to the installation site. The main downside is that polyethylene is poor at conducting heat.

Mixed different conductive materials

"In my project, the goal was to improve the heat conducting properties of so-called high-density polyethylene. I started with commercial polyethylene materials and added substances that we know have good heat conducting properties. By this method, we got a composite material with improved thermal conductivity. Talc proved to give the best overall properties compared to, for example, copper. Copper does indeed have better thermal conductivity, but as an additive in the composite material, this property decreases," he says.

The advantage of this composite material, which has good thermal conductivity as well as good mechanical properties, is that you do not have to drill such deep boreholes, and that the performance of the system will increase, and the total investment cost can thus be reduced. All in all, this leads to better energy management and a reduced impact on the environment.

"The EU has set the goal that we will reduce our emissions by 95 percent during the period 1995–2050 while at the same time as we must rely more on renewable energy. So it is important to work towards this goal on all fronts," he concludes.

More information: Thermally Conductive High-Density Polyethylene Composites for Ground Heat Exchangers: hb.diva-portal.org/smash/record.jsf?pid=diva2%3A1458901&dswid=-4235