Achieving edge-closed graphene nanoribbons by squashing carbon nanotubes

Long, narrow graphene nanoribbons (GNRs) with smooth edges, sizable bandgap and high mobility are highly desirable for electronic and optoelectronic applications. However, efficiently preparing such GNRs is difficult. Recently, Changxin Chen and his colleagues report that sub-10-nm-wide semiconducting graphene nanoribbons with atomically smooth closed edges can be produced by squashing carbon nanotubes using a high-pressure and thermal treatment. The study was published online September 6 in Nature Electronics.

One major obstacle to the application of graphene in electronics and optoelectronics has been that two-dimensional graphene is a semimetal with the zero bandgap. One solution is to use one-dimensional graphene nanoribbons (GNRs) with a narrow width. Previous studies had demonstrated that the GNRs with a width of <10 nm are all semiconducting. In particular, GNRs with a width less than 5 nm have a sizable bandgap, which can meet the application requirements of high-performance logic devices. The mobility and conductivity of GNRs are highly dependent on the degree of edge roughness due to edge scattering effects.

On the other hand, it is still a large challenge to obtain the 100% semiconducting single-walled carbon nanotubes (SWCNTs) based on present separation or growth technology of CNTs. "This also grants narrow GNRs a key advantage over SWCNTs in producing all-semiconducting devices for the application in future integrated circuits," said Changxin Chen, the first author and corresponding author of this work and a professor of electronic science and technology at Shanghai Jiao Tong University.

Unfortunately, high quality GNRs that are ultra-narrow and long are difficult to synthesize—particularly ones with smooth edges throughout the ribbon length. Thus, a method to efficiently produce narrow and long GNRs with atomically smooth edges is an urgent focus of the research community.

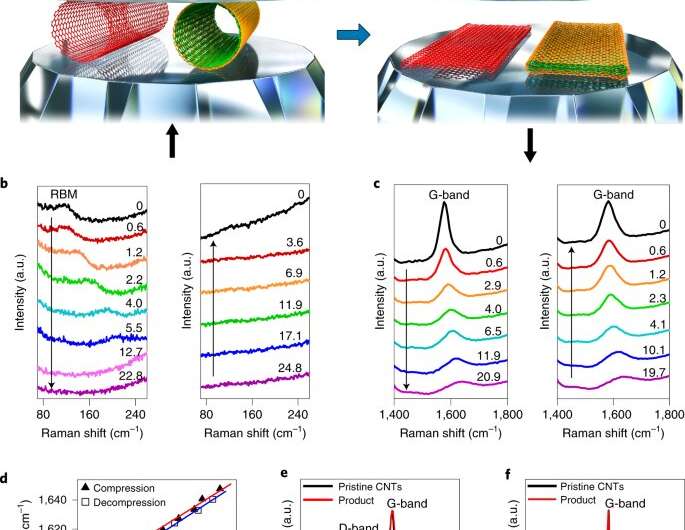

In the work, a diamond anvil cell (DAC) was used for the high-pressure treatment of CNTs. The CNT samples were loaded and sealed in a sample chamber in the centre of a pre-indented tungsten gasket that was then compressed between two diamond anvils. Figure 1 illustrates the structural change in CNTs before and after the high-pressure and thermal treatment, where the pristine CNTs are squashed into GNRs after treatment. The application of a high non-hydrostatic pressure and suitable thermal treatment along with the stabilizing effect of innate defects in CNTs contribute to the realization of irreversible radial deformation for CNTs. This makes CNTs be squashed into GNRs. The GNRs obtained from squashed CNTs have atomically smooth, closed edges and few defects.

With this approach, GNRs narrower than 5 nm were obtained, and a GNR width down to 1.4 nm was recorded, which is the one of the narrowest among GNRs fabricated using top-down approaches reported to date. Edge-opened GNRs could also be prepared via using an oxidant, HNO3, to selectively etch the edges of the squashed CNTs under high pressure. A high yield up to 54% could be achieved to squash single-walled and double-walled CNTs into edge-closed GNRs. A typical field-effect transistor (FET) constructed by a 2.8-nm-wide edge-closed GNR exhibits a high comprehensive performance with high Ion/Ioff ratio (>10^4), on-state conductivity (7.42 mS) and device mobility (2,443 cm^2 V^−1 s^−1) achieved concurrently. And a bandgap of ~494 meV is estimated for this GNR. High-yield synthesis of narrow semiconducting GNRs with high mobility and sizable bandgap is crucial for its large-scale device integration.

The method in this work provide a route to produce high-quality, narrow, and long semiconducting GNRs and to control the GNR's edge types for exploring their fundamental properties and practical applications in electronics and optoelectronics. It is a significant advance in the production of high-quality GNRs and high-performance GNRFETs. "Comparing with the methods reported earlier, this new approach is capable of producing much narrower GNRs," Changxin Chen said. "Moreover, the atomically smooth edges throughout the entire GNR can be achieved by our method, resulting in high material and device mobility."

"Taking advantage of our method's high yield, it is hopeful to scale up the synthesis by further using a multi-anvil apparatus or a large-volume press. Importantly, this method can also be extended to make other material-based nanoribbons from squashed nanotubes and to flatten other fullerene materials," said Changxin Chen.

More information: Changxin Chen et al, Sub-10-nm graphene nanoribbons with atomically smooth edges from squashed carbon nanotubes, Nature Electronics (2021). DOI: 10.1038/s41928-021-00633-6