This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Efficient and scalable moisture-electric generators made from ionic hydrogel

Finding a simple and efficient green energy conversion technology is an essential component of the plan to achieve carbon neutrality and sustainable green energy while also satisfying the increased demand for electrical power.

A moisture-electric generator (MEG), which uses chemical energy from atmospheric moisture to generate electricity directly without causing pollutants and harmful gas emissions, is an emerging technology in the energy field.

Practical green power source

However, most MEGs suffer from intermittent electrical signals and low currents. In addition, large-scale integration and practical applications have not yet been achieved. To address these problems, Prof. Xiaoming Tao, Director of Research Institute for Intelligent Wearable Systems, and her team have created a novel and efficient ionic hydrogel moisture-electric generator (IHMEG) that is versatile, flexible, lightweight and has all-weather adaptable features. The research is published in the journal Advanced Materials.

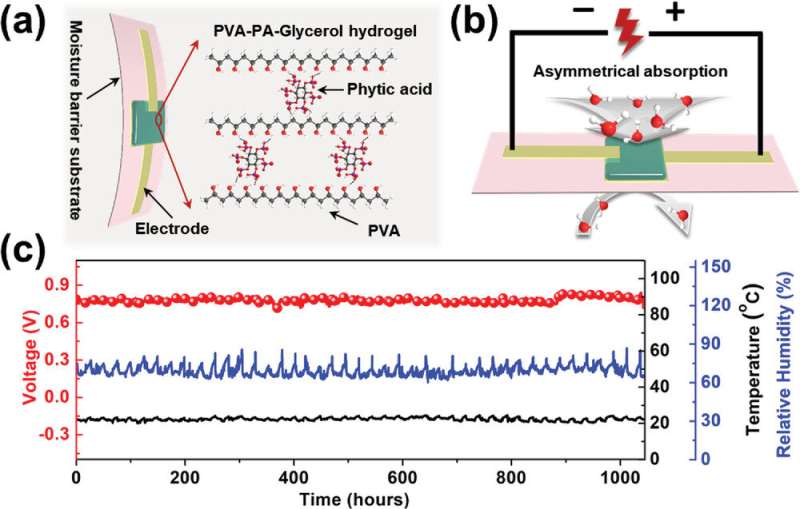

The IHMEG operates stably in a wide range of environmental conditions from 10% to 85% relative humidity (RH) and from -24°C to 60°C. This provides a promising green power source for Hong Kong, where most of the RH fluctuates from 40% to 90% during the year.

Applicable energy source

Thanks to the synergistic effect of the moisture-absorption capability and fast ion transport capability in the ionic hydrogel network, a single IHMEG unit of 0.25 cm2 can continuously generate direct-current electricity with a constant open-circuit voltage of ≈0.8 V for more than 1,000 hours, a high short-current density of 0.24 mA cm−2, and power density of up to 35 µW cm−2.

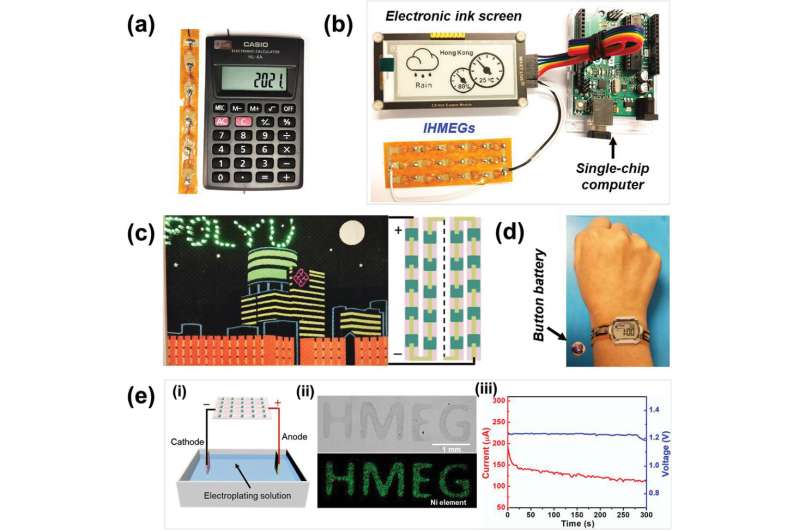

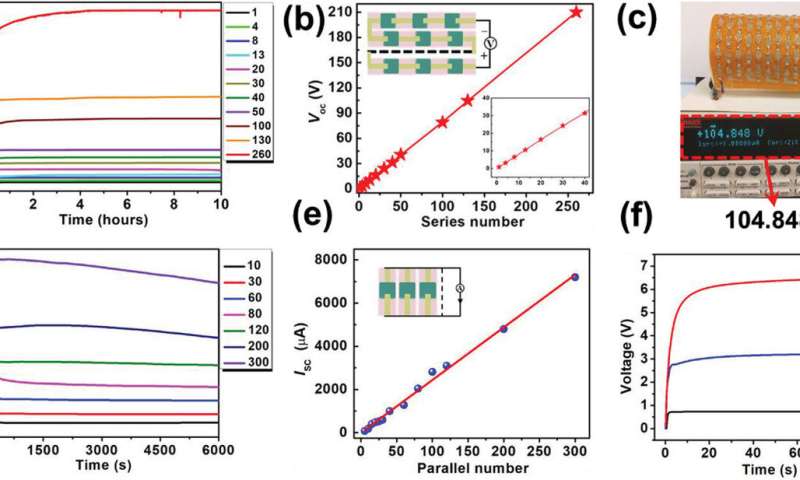

Importantly, the large-scale integration of IHMEG units can be readily achieved and offers a device with a voltage up to 210 V, which is capable of directly driving numerous commercial electronics, including electronic calculators, energy watchbands, electronic ink screens and light-emitting-diode arrays. Also, the IHMEG power device is successfully employed to electroplate metal nickel (Ni) structures on the millimeter scale. This is a significant advance and proves the practical application of scalable IHMEG with sufficient energy.

Moreover, an IHMEG direct-circuit (DC) power source can be easily designed and fabricated by connecting multiple IHMEG units in serial, parallel fashion or a combination of these according to operating requirements. With the progress in spontaneous energy generation from ubiquitous moisture, the IHMEG device shows great potential to develop versatile, efficient, scalable and green power sources for self-powered IoT and wearable electronics systems.

-

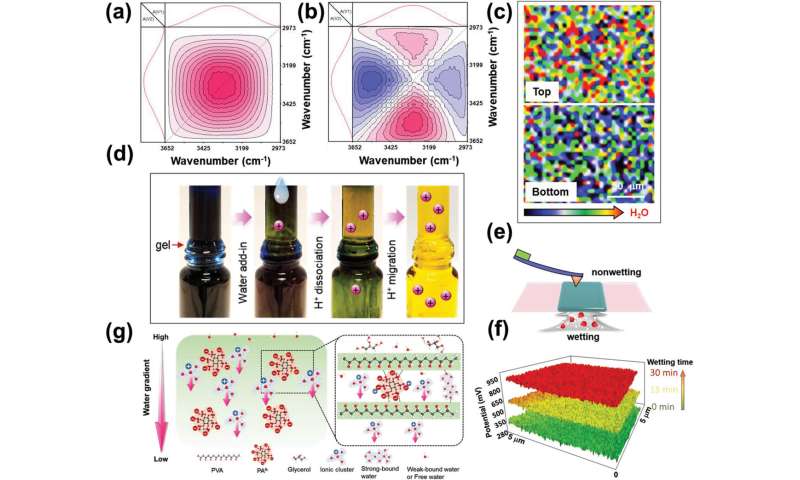

The underlying mechanism of IHMEG. 2D-FTIR correlation spectra in the 3700–3000 cm−1 wavenumber region: a) synchronous; b) asynchronous contour maps for IHMEG samples when exposing in the air. The pink area and blue area denote the positive and negative correlation peaks, respectively. c) The water diffusion difference between the top and the bottom surface of hydrogel by 2D Raman mapping after 120 min. d) Photos of the experiment for visualizing the dynamic change of the moisture-induced ionic diffusion process. A piece of the hydrogel is sandwiched between the open ends of two cylindrical containers, the upper tube has two open ends and the bottom one has one open end and one closed end. They are filledwith bromophenol blue/isopropanol solution. Water is added into the upper tube through the open end. The color change in the two tubes indicates the dynamic diffusion of dissociated protons with water diffusion. e) Schematic plot of the setup for the Kelvin probe force microscope (KPFM) test and f) the potential change of hydrogel. A piece of hydrogel (250 μm thickness) absorbed moisture from one side and the other side was covered without wetting. The potentials of the two sides are detected by KPFM. The scan range is 5 × 5 μm. The lower right picture shows the potential increment of the hydrogel after water diffusion from the wetting side to non-wetting side from 15 to 30 min. g) The proposed mechanism of moisture-induced ionic diffusion process. Credit: Wiley Online Library -

Power devices by integration of IHMEG units in serial or parallel packages as a practical DC source for commercial low-power electronics. a) Voltage output of a serial IHMEG units with different series number. The test condition is 65% RH. b) The Voc related to the serial number of device units. Inset is the equivalent circuit scheme of serial IHMEG units. c) The picture of the voltage output of flexible IHMEG with 130 units in series. d) Current output of a single IHMEG package with different parallel number. e) The Isc related to the parallel number of device units. Inset is the equivalent circuit of the parallel IHMEG package. f) Voltage–time curve of a commercial capacitor with 47 μF directly charged by a serial IHMEG units with 1, 4, and 8 units. Credit: Wiley Online Library

More information: Su Yang et al, Ionic Hydrogel for Efficient and Scalable Moisture‐Electric Generation, Advanced Materials (2022). DOI: 10.1002/adma.202200693