This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Researchers develop new method of programmable multi-interface droplet printing

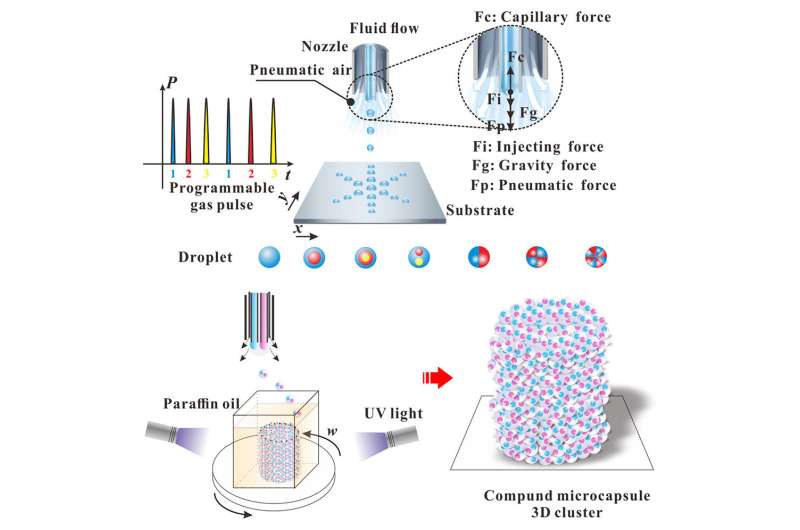

Zhu Zhiqiang, Prof. Si Ting, Prof. Xu Xiaorong, and their colleague from the School of Engineering Science, University of Science and Technology of China (USTC) of the Chinese Academy of Sciences (CAS), recently proposed a new method for patterning soft materials named programmable pulsed aerodynamic printing (PPAP). The study was published online in the journal Matter.

The controllable generation and patterning of soft materials play an important role in biology, medicine, chemistry, material science, and engineering. Droplet-based printing acts as an efficient strategy capable of precisely adjusting the size, structure, and composition of microdroplets, thus it is increasingly being applied in the fields of soft robotics, bioprinting, and others.

As a fundamental index in soft material printing, the Z number, defined as the reciprocal of the Ohnesorge number, represents the applicability and flexibility of materials. It remains a challenge for current methods to achieve precise printing of multi-interface droplets with a wide range of Z numbers.

To widen the Z number range, the researchers introduced the technique of PPAP making use of the external flow driving method to provide strong shear in droplet microfluidics based on the droplet generation mechanism and the innovative combination of multi-compartment droplet manufacturing and 3D printing.

This active force application method was also capable of reducing the size and increasing the printing speed, which simplifies the manufacturing of multi-compartment droplets and is fundamental in micro-nano functional structures and devices.

The researchers then built a theoretical model for multi-compartment droplet manufacturing, revealing the mechanical principle of PPAP. They checked the stability and repeatability of droplet generation through numerical simulation.

This study demonstrated that PPAP shows broad potential in cell encapsulation, controlled drug release, self-assembly, 3D microstructure, etc. A new path for the advancement of micro-nano functional structures and devices can now be envisioned.

More information: Zhiqiang Zhu et al, Programmable pulsed aerodynamic printing for multi-interface composite manufacturing, Matter (2023). DOI: 10.1016/j.matt.2023.04.017