This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Scientists develop stretchable robotic fabrics that enable error-prone robotic modules to march in formation

Robotic fabrics that can shrink, grow in size and move with precision are becoming a reality, thanks to new research from scientists at the University of Sheffield.

The study, led by Dr. Roderich Gross from the University's Department of Automatic Control and Systems Engineering, has demonstrated for the first time how low-power robotic modules—approximately the size of a 50p coin—can connect together via an elastic mesh and move reliably in the same direction, forming an intelligent robotic fabric.

Published in Nature Communications, the study is the first to show that elastic links enable error-prone robotic modules to march in formation, outperforming modules that are rigidly linked, or not linked at all.

The Sheffield scientists say the research paves the way for the development of ultra-low-power robotic fabrics that navigate spaces inaccessible to humans such as underground water pipes to look for cracks, or that can shrink and be deployed inside the human body to provide medical monitoring or treatment.

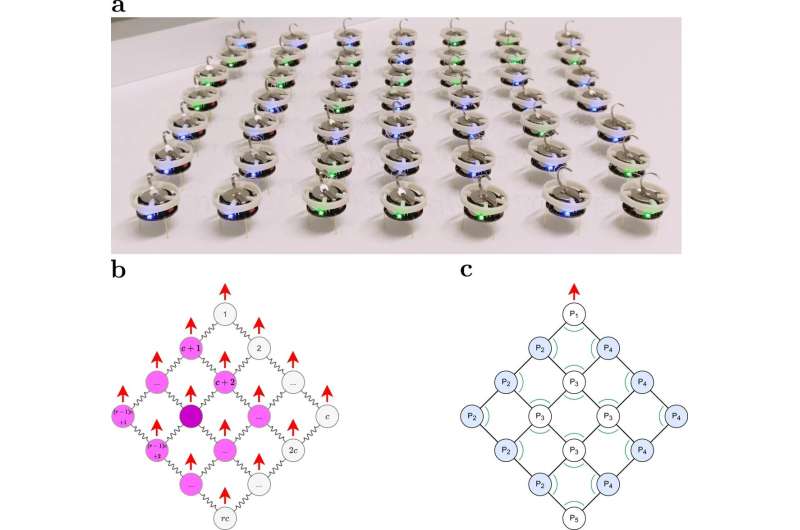

The prototype fabrics developed in the study are made up of small robotic modules—known as Kilobots—that are low power and have low processing capabilities due to their limited size. Each Kilobot uses vibration motors to move, but cannot precisely control its own direction. When part of the elastic mesh, it communicates with other nearby modules such that the group collectively decides how best to move and behave.

Groups of Kilobots and other small modules usually are not physically linked, but the Sheffield study shows how coupling the modules together in an elastic mesh enables them to move more reliably.

Dr. Roderich Gross, Senior Lecturer in Robotics and Computational Intelligence, at the University of Sheffield, said, "Previous studies have looked at intelligent fabrics that sense their surroundings or change appearance. This study looks at intelligent fabrics that move from one place to another, meaning they could deploy themselves without human assistance. In the future, such fabrics could effectively navigate spaces inaccessible to humans, for example, for inspecting the inside of a jet engine.

"In the long term, self-moving, stretchable fabrics may be deployed in medical applications, for example, wrapping around a damaged section of an organ and then monitoring or stimulating it at high spatial resolution."

In the study, the researchers produced robotic fabrics comprising 49 Kilobot modules. Their experiments show that a single module can't independently move in a straight line. A fabric of 16 modules can move in a straight line, but only for a short duration. The more modules are part of the fabric, the more successful it moves in a coherent direction.

Further experiments in the study show a fabric moving successfully along a desired path—a circle—and a fabric first changing shape to fit through an imagined smaller space and then restoring its original shape. When the modules are part of a rigid mesh, however, they are unable to move in a coherent direction.

Similar to the way birds move in flocks, the research shows that a large number of individuals can more effectively negotiate where to move, than a smaller number—known as the many-wrongs principle.

However, unlike previous research on the many-wrongs principle, the modules studied by the Sheffield academics do not solely rely on their ability to gather and use information. Rather, the negotiation is aided by the physical bonds within the elastic mesh. This means that the modules rely less on energy-intense perception and thinking to act in a coherent way, which could aid their miniaturization and the realization of fabrics comprising thousands of modules.

More information: Federico Pratissoli et al, Coherent movement of error-prone individuals through mechanical coupling, Nature Communications (2023). DOI: 10.1038/s41467-023-39660-6