This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Researchers propose linear scan-based vat photopolymerization for 3D printing ultra-high viscosity resin

Compared with other three-dimensional (3D) printing techniques, vat photopolymerization (VPP) is a widely adopted technique for its advantages of high-efficiency, large build envelope, economic, and versatile material options.

However, high fluidity of the ultraviolet (UV)-curable resin is required due to the current printing mechanism of the bottom-up vat photopolymerization 3D printing technique. This viscosity requirement limits the properties of the UV-curable which is usually required to be diluted before usage (up to 5,000 cps of viscosity). The original mechanical properties of the oligomers are sacrificed by the introduction of reactive diluent. The key technical difficulty of 3D printing high-viscosity resins lies in the leveling of the resin and deformation of the cured parts from the film.

In a study published in Nature Communications, the research group led by Prof. Wu Lixin from Fujian Institute of Research on the Structure of Matter of the Chinese Academy of Sciences proposed linear scan-based vat photopolymerization (LSVP) for 3D printing ultra-high viscosity resin.

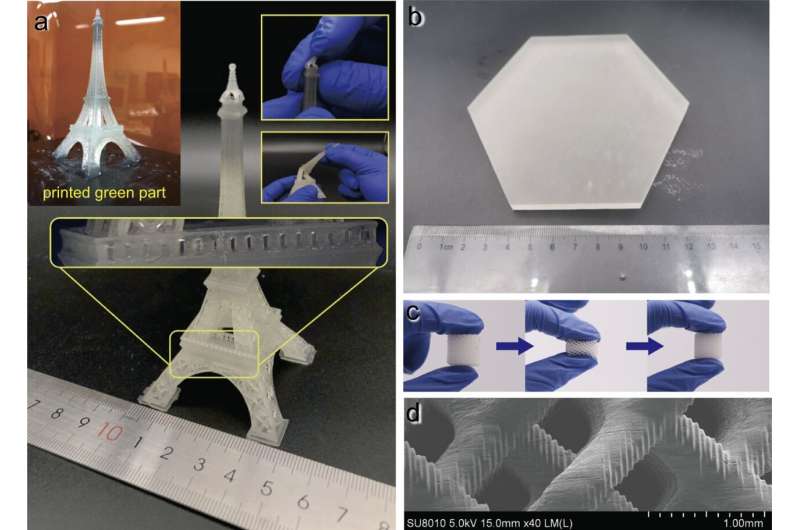

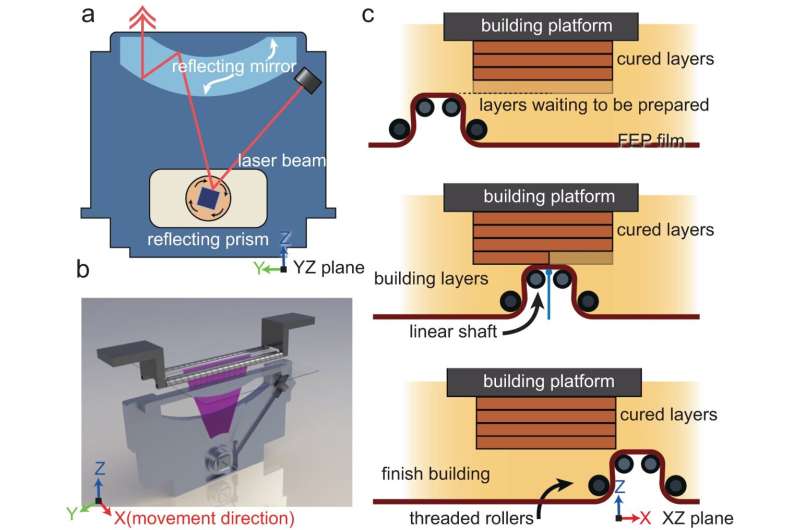

The researchers employed four rollers to create an isolated printing area on the resin tank, which enables the simultaneous curing of the resin and the detachment of cured part from the resin tank. The prototyping of this LSVP system is capable of printing high viscosity UV-curable resin at a maximum viscosity of 600,000 cps.

The unique deformation approach of printed parts and the film also makes the printing of 100% solid parts available without orientation. This fabrication approach greatly widens the processing windows of vat photopolymerization.

Additionally, the researchers evaluated the LSVP system to study how the viscosity affects the mechanical properties. They compared UV-curable resins with different proportion of 4-acryloylmorpholine (ACMO) and CN8888NS. The UV-curable resin comprising high content of CN8888NS exhibited excellent mechanical properties, particularly when the content of ACMO reached 10 wt%. The strain of the specimen is higher than 400%, and the strength is higher than 20 MPa.

Moreover, the researchers revealed that besides elastomers, 3D printed materials with high toughness are also of interest for industrial applications.

This study proposes a facile and time-saving UV-curable 3D printing method called LSVP. It is expected that with this LSVP system, various oligomers could be applied to prepare 3D printable UV-curable resins without the aid of reactive diluents.

More information: Zixiang Weng et al, 3D printing of ultra-high viscosity resin by a linear scan-based vat photopolymerization system, Nature Communications (2023). DOI: 10.1038/s41467-023-39913-4