November 27, 2023 dialog

This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

trusted source

written by researcher(s)

proofread

Development of a high flow rate cantilever fan

Cantilever fans move air through a flapping action, similar to hand-fans. Commercially available, they are combined with a piezoelectric bender, which provides their motive force. These fans are low noise, low power and have a low flow rate. They have a useful niche for increasing the cooling of electronics beyond that of natural convection, without requiring high flow rate.

I have developed a cantilever fan design with a more than 100-fold increased volumetric flow rate, and I have demonstrated it can be competitive with axial fans in flow rate and noise level. I believe this enhancement could open opportunities for wider adoption of cantilever fans in moving air and cooling applications.

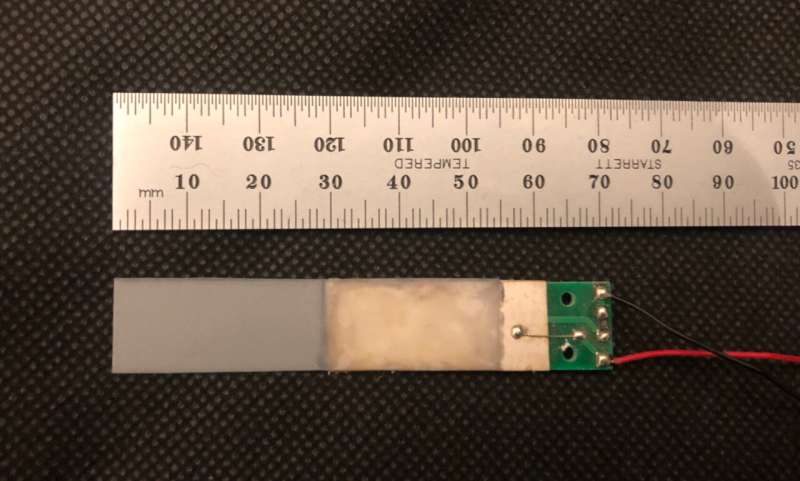

A typical piezoelectric fan is shown in figure 1. It consists of a polymeric fan blade and a piezoelectric bender. When the bender vibrates at the resonant frequency of the fan blade, the fan tip moves with a deflection of a few centimeters and thus moves air. As there is no inlet or outlet to the fan, the air movement is dominated by recirculating vortices. However, there is some net forward momentum imparted to the air, thus a modest net flow of air.

The design I developed is shown in figure 2. In the center of the rig are three stainless steel fan blades painted yellow for clarity. Each fan blade is 15 cm by 14 cm. The system is driven by two custom linear motors connected to either end of a vibration beam, which in turn is connected to the base of the three fan blades. The fans are driven at 20 Hz, which is a frequency below that of human hearing. This limits the audible sound to only the turbulent flutter of the air moving past the blades.

Approach to increased flow rate

The large increase in flow rate can be attributed to the combined effects of several factors. The linear motors are substantially more powerful than piezoelectric benders, the fan blades are larger, the fan blades are made from spring steel, multiple fans are combined into arrays, and strategic placement of shrouding reduces vortices.

My paper, published in Results in Engineering, shows that the maximum speed of the fan tip depends on the strength of the material (more specifically, the endurance limit), the Young's modulus and density. Spring steel has an exceptionally high endurance limit, so the tip speed of the fan is higher than polymeric fan blades.

Using more than one fan in an array is also important to produce a high flow rate. My paper shows that a minimum of two fans are required to encapsulate a cuboid of air, which is accelerated forward, as the fans swing left and right. This can be seen in the paper's accompanying slow-motion video.

The strategic placement of shrouds contributes to the high flow rate by reducing recirculation vortices. By placing shrouds at the top and bottom edges of the blades, the air is prevented from circulating from the high to low pressure sides of the fan. Also, placing shrouds at the left and right of the fan arrays prevents backflows and creates a well-defined inlet area.

Context and conclusion

The vast majority of commercial fans can be classified as axial, centrifugal, mixed-flow, or cross-flow fans. The most recent addition to this list was the cross-flow fan, invented in 1893. Each of these fan types has its strengths and has found applications that play to these strengths. This cantilever fan design with comparable flow rate to an axial fan could find equally useful applications.

Two of its unique strengths are the elimination of any bearing or rubbing surface, and due to the lack of rotation, it has the freedom to create different aspect ratios of the fan inlet rectangle. The work presented in the paper has no intellectual property protection, and is therefore free for further experimentation.

This story is part of Science X Dialog, where researchers can report findings from their published research articles. Visit this page for information about ScienceX Dialog and how to participate.

More information: Peter D. Leaback, A high volumetric flow rate infrasonic cantilever fan, Results in Engineering (2023). DOI: 10.1016/j.rineng.2023.101602

Peter Leaback qualified with a BSc(Hons) in Computer Science from Kingston University, London in 1992. He spent 15 years designing algorithms for silicon chips and is now an independent inventor with a focus on climate change mitigation.