This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

proofread

New electrochemical system enables efficient metal recovery from industrial wastewater

A research team at Tsinghua University led by Professor Huijuan Liu has developed a new electrochemical system that promises to revolutionize metal recovery from industrial wastewater. The research was published in Engineering.

Industrial wastewater poses significant environmental hazards due to heavy metal pollution. Current methods for metal recovery, such as electrodeposition, suffer from interfacial ion transport limitations, resulting in slow and low-quality recovery. In their study, the team proposed a novel approach that integrates a transient electric field (TE) and swirling flow (SF) to improve mass transfer and promote interfacial ion transport simultaneously.

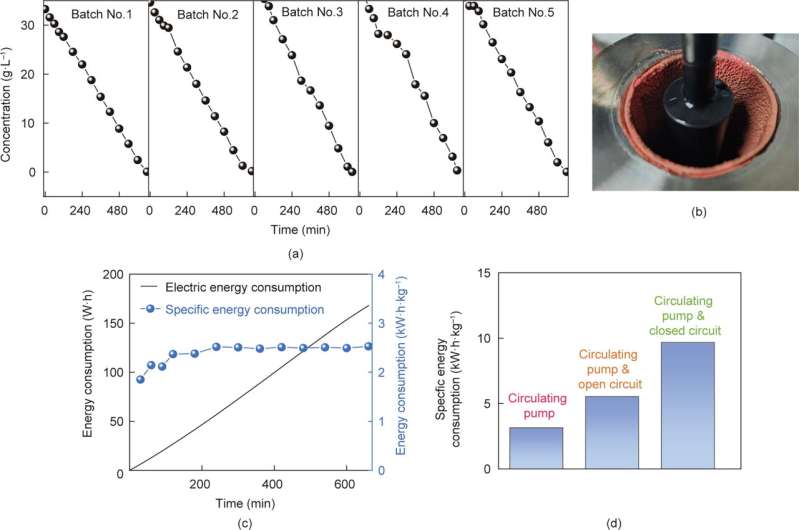

The research team explored the effects of different operating conditions, including operation mode, transient frequency, and flow rate, on metal recovery. They discovered that the optimal conditions for rapid and efficient sequential recovery of copper in TE&SF mode were achieved with low and high electric levels of 0 and 4 V, a 50% duty cycle, a 1 kHz frequency, and a 400 L/h flow rate. The kinetic coefficients of TE&SF electrodeposition were found to be 3.5−4.3 times and 1.37−1.97 times that of single TE and SF electrodeposition, respectively.

To gain insights into the process, the team simulated the deposition process under TE and SF conditions. The results confirmed the efficient concurrence of interfacial ion transport and charge transfer, leading to rapid and high-quality metal recovery. The combined deposition strategy demonstrates not only effective metal pollution reduction but also promotes resource recycling.

This innovative approach overcomes the limitations of interfacial ion transport in conventional electrodeposition methods. The team successfully improves bulk and interfacial ion transport by coupling a transient electric field with turbulent flow, thus enhancing the reaction kinetics. The synergy of the transient electric field and swirling flow achieves not only rapid metal recovery but also deposits with homogeneous compositions and uniform morphologies.

Furthermore, the system shows wide applicability in recovering metals with redox potentials higher than those of hydrogen evolution and water reduction. This capability allows for the high-value recovery of precious and heavy metals, making it a valuable asset for industries dealing with metal waste.

The research conducted by Professor Huijuan Liu and her team provides new insights into efficient metal recovery from industrial wastewater. Their findings open up possibilities for environmentally friendly and resource-efficient metal recycling processes, contributing to the reduction of pollution and the preservation of valuable resources.

More information: Li Chen et al, Toward Efficient Metal Recovery from Industrial Wastewater: An Electrochemical System in Potential Oscillation and Turbulence Mode, Engineering (2024). DOI: 10.1016/j.eng.2023.12.002