This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

trusted source

proofread

Researchers develop model for cost-effective and environmentally friendly pulp and paper industry

Aerobic treatment of industrial wastewater from the pulp and paper industry is the most expensive treatment step in the purification process. New research published in Environmental Technology & Innovation shows how the purification of wastewater from pulp manufacturing can be made more energy efficient by predicting the oxygen-transfer rate and thereby enabling a way to regulate the aeration.

"Our published study is about analyzing oxygenation of water in order to predict the oxygen-transfer rate depending on the concentration of surfactants in the water," says Kamal Rezk, Senior Lecturer in Environmental and Energy Systems. The study focuses on the surfactant lauric acid, which is a common substance in contaminated water from the pulp and paper industry.

Without sufficient knowledge of the oxygen-transfer rate, there is a risk of excessive aeration of the water, which increases operating costs as a result of increased energy demand in the aeration system. Another risk is inadequate aeration, which leads to insufficient purification and limits production as a result.

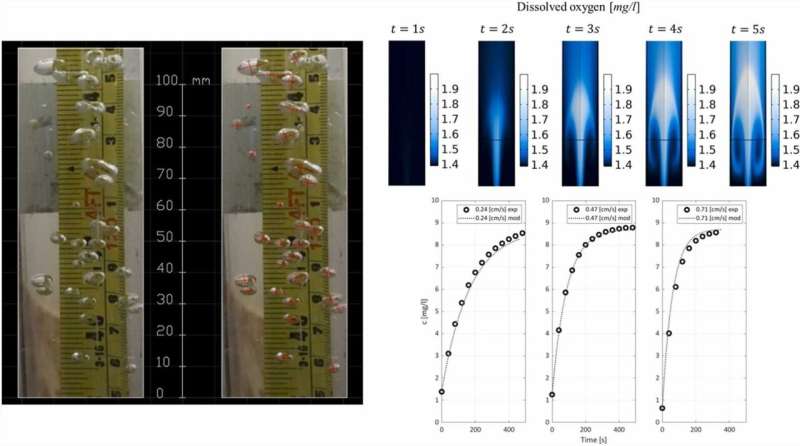

"We have conducted a combined laboratory and numerical study where the oxygenation has been measured based on different air flows and concentrations of lauric acid on a laboratory scale," says Wamei Lin, Senior Lecturer in Environmental and Energy Systems. "Variations in bubble size have been analyzed and used as input for the simulation model."

Model for optimized purification

The researchers have developed a numerical calculation model to be able to predict the oxygen-transfer rate based on air flow, concentration of lauric acid and, thus, a representative bubble size. The model can predict the oxygen-transfer rate of clean water at low air flows and low concentrations of lauric acid.

"The wastewater from the pulp- and paper industry are cleaned based on strict environmental requirements and the crucial factor in the purification process is the aeration," says Rezk. "If you don't aerate enough, the purification will not be up to standards and you have to slow down the production rate. Thanks to our research findings, production downtime can be avoided, which is of great economic importance for the pulp and paper industry."

More information: Kamal Rezk et al, Numerical and experimental analysis of oxygen transfer in bubble columns: Assessment of predicting the oxygen-transfer rate in clean water and with surfactant solutions, Environmental Technology & Innovation (2024). DOI: 10.1016/j.eti.2023.103522