This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Liquid metal may point way to wearable ultrasound devices

The best-known byproduct of ultrasound—so named because its frequencies exceed the range of the human ear—is, in fact, not audio but visual: 2D imagery, often of a fetus maturing in the womb. But ultrasound has also found a place in other corners of the medical realm, from assessing blood flow to examining suspicious lumps and diagnosing disease.

That diagnostic capability has recently motivated biomedical engineers to design wearable ultrasound devices that can continuously monitor for signs of trouble, particularly by tracking blood flow or the rhythmic motion of the heart. Those wearable devices will ideally consist of stretchable material that accommodates movement and the human form.

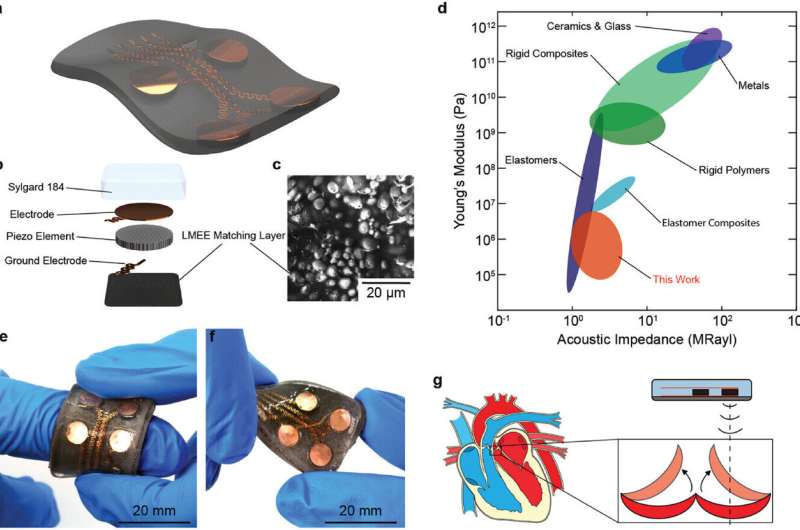

Unfortunately, a stubborn engineering challenge stands in the way. Ultrasound relies on transducers, which both emit the high-frequency sound waves and detect those reflected back by various structures in the body, ultimately forming an image. Reflections occur wherever the waves cross a boundary between two materials that offer different levels of resistance, or acoustic impedance.

To overcome the differing acoustic impedance that waves face in passing from a transducer to the human body—a mismatch that ruins acoustic transmission—engineers install so-called matching layers between the two. Most particles or materials employed as matching layers, though, have proven too rigid for use in pliable, wearable devices.

Nebraska's Eric Markvicka, Ethan Krings and colleagues have spent years investigating the properties and potential applications of liquid metal droplets, which include gallium-based alloys. With an eye toward designing a more conforming but still-functional matching layer, the Husker researchers embedded various volumes and sizes of gallium-based droplets in a soft silicone.

When saturating the silicone with roughly 70% of the droplets, the team found that the resulting density of the matching layer increased its acoustic impedance by more than 400%—to levels approaching those boasted by more rigid counterparts. And that impedance declined by only 13% when the matching layer was mechanically strained in ways akin to what it might endure as part of a wearable device.

The team then collaborated with Nebraska's Greg Bashford and Ben Hage to integrate its stretchable matching layer into a wearable ultrasound prototype. When presented with a moving object that simulated the motion of a heart valve or other tissue, the prototype successfully registered that movement, demonstrating its potential as a diagnostic device.

Their findings are published in the journal Advanced Functional Materials.

Modifying the liquid metal droplets, whether by tailoring their surfaces or their alloys, could further improve the performance of the matching layers that incorporate them, the team said. As the medical field moves toward wearable devices, the researchers said, those matching layers could find their way into specialized ultrasonic sensors that help detect multiple diseases and conditions.

More information: Ethan J. Krings et al, Acoustic Properties of Stretchable Liquid Metal‐Elastomer Composites for Matching Layers in Wearable Ultrasonic Transducer Arrays, Advanced Functional Materials (2023). DOI: 10.1002/adfm.202308954