This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

proofread

Reduced risk of PEMFC flooding by gas diffusion media hydrophobic gradient

Fuel Cell Vehicles (FCVs) are typically powered by polymer electrolyte membrane fuel cells (PEMFCs), which convert the chemical energy of hydrogen and oxygen into electricity and produce water in the cathode.

In PEMFCs, both water and reaction gas are transferred through the gas diffusion media (GDM), a porous media composed of a micro-porous layer (MPL) and a gas diffusion layer (GDL). When water accumulates in GDM, the mass transfer in PEMFC will be blocked, leading to flooding. This, in turn, results in a decrease in the output performance and service life of PEMFC.

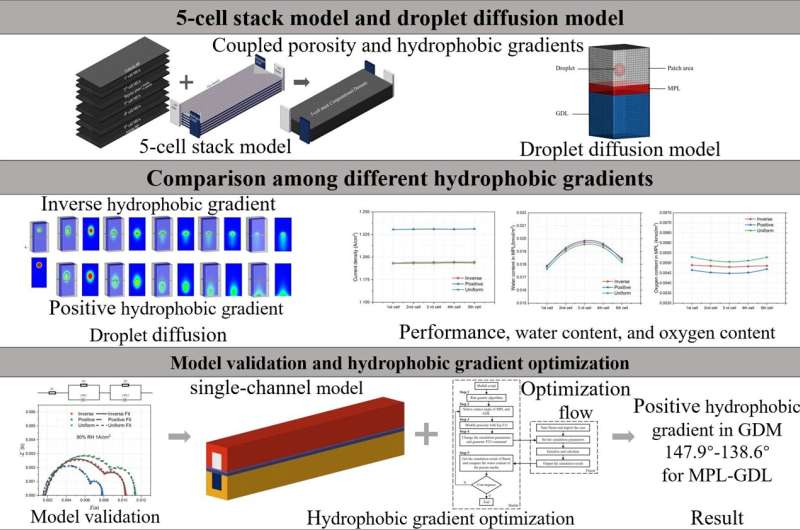

In a study published Fundamental Research, a group of researchers from China outlined a GDM design—GDM hydrophobicity gradient. Specifically, the hydrophobicity gradient reduces the risk of flooding by accelerating the water transport in GDM and improving reaction gas transport.

"The wettability of a material is demonstrated as contact angle, which is the angle of a liquid interface meets a solid surface," explains the study's lead author, Qinwen Yang, an Associate Professor in New Energy Power System Design at the College of Mechanical and Vehicle Engineering, Hunan University.

"A high contact angle indicates hydrophobicity (water-repelling), while a low contact angle indicates hydrophilicity (water-attracting). The different contact angles form the hydrophobicity gradient and change the water behavior to improve the mass transfer ability in GDM."

Notably, polytetrafluoroethylene (PTFE) is widely used to treat GDM to form different hydrophobicity. However, PTFE treatment decreases GDM porosity and degrades the performance of PEMFC.

To that end, at the simulation and optimization stage, the team combined experimental data and empirical equations to investigate the coupling relationship among PTFE content, hydrophobicity, and porosity. The researchers then studied the effect of the hydrophobicity gradient on the mass transfer process.

"We found that the hydrophobicity of MPL is higher than GDL, which speeds up the transfer of water in GDM and reduces the water accumulated on the interface of MPL and GDL," shares Qinwen Yang. "This enhances the oxygen transport capacity of GDM."

The GDM hydrophobicity gradient design provides a new strategy for water management.

"Designing different GDM hydrophobicity gradients according to the operation conditions of FCVs can further improve the output performance and service life of PEMFC," adds Qinwen Yang. "This could also promote the commercialization of FCV."

Going forward, the team intends to conduct relevant research to improve water management for PEMFC systems.

More information: Qinwen Yang et al, Hydrophobicity gradient optimization of fuel cell gas diffusion media for its application in vehicles, Fundamental Research (2024). DOI: 10.1016/j.fmre.2024.01.007