This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

trusted source

proofread

Research team develops aluminum alloy that may reduce the risk of electric vehicle fires

Dr. Hyeon-woo Son and his research team from the Department of Aluminum in the Advanced Metals Division at KIMS have successfully developed an aluminum alloy for electric vehicles that dramatically improves thermal stability. The paper is published in the Journal of Materials Research and Technology.

The team identified a new mechanism by which the nanostructures inside aluminum alloys work and found that the alloys they developed improved thermal stability by up to 140% compared to materials from leading overseas companies.

Existing aluminum battery enclosure materials continuously deteriorate due to the heat emitted by the battery, leading to a significantly increased the risk of accidents as electric vehicles age. The newly-developed aluminum alloy can enhance thermal stability by incorporating various trace elements to the existing 6000 series aluminum alloy, thereby delaying the thermal deterioration of enclosure materials due to heat generation.

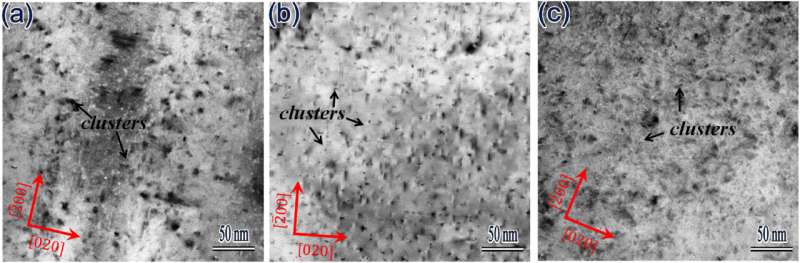

The research team established a new database by introducing dozens of trace elements and analyzing nanostructures through state-of-the-art techniques such as transmission electron microscopy and 3D atom probe tomography. Based on this, they were able to confirm that several elements can improve thermal stability.

The aluminum alloy with thermal stability improvement technology can exhibit excellent properties in parts used for extended periods in high- temperature environments, such as electric vehicle battery enclosure materials or structural materials for supersonic aircraft.

Traditional techniques for improving thermal stability are typically confined to utilizing a database of elements that have long been employed in aluminum alloys. This research is significant in that it expands the database of thermal stability enhancement techniques and introduces new directions for alloy design.

The electric vehicle battery enclosure material market is anticipated to grow at an average annual rate of 8.4%, reaching USD 863.3 million by 2029 from USD 464.9 million in 2020. Presently, it trails behind advanced overseas companies in terms of technological competitiveness. However, it is expected that local production through this technology is expected not only to drive import substitution but also to facilitate exports.

This research was conducted as part of the fundamental project of the Korea Institute of Materials Science and the National Laboratory (N-Lab.) project. As a result of this research, the team has published three SCI-level papers and filed two patents.

They have completed fundamental research on aluminum alloy manufacturing technology with excellent thermal stability and are now conducting follow-up research with the aim of advancing the technology through applied research and transferring it to domestic aluminum battery enclosure material manufacturers.

More information: Zhirou Zhang et al, Effect of Ag and Ge on the precipitation behavior and resultant properties of AA6061 alloys, Journal of Materials Research and Technology (2023). DOI: 10.1016/j.jmrt.2023.12.053