This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

trusted source

proofread

Sustainable electrification: Managing resource demands for future electric vehicles

With goals to limit CO2 emissions, many countries have set targets to phase out internal combustion vehicles in favor of electric vehicles (EVs). Japan has set a target for 20%–30% of all car sales to be battery electric vehicles (BEVs) and plug-in hybrid electric vehicles (PHEVs), and 30%–40% of car sales to be hybrid electric vehicles (HEVs) by 2030.

The U.S. plans for 50% of new vehicles to be zero-emission by 2030, while Germany wants to have 15 million EVs on the road by 2030. These goals raise concerns about the raw material demand for EVs.

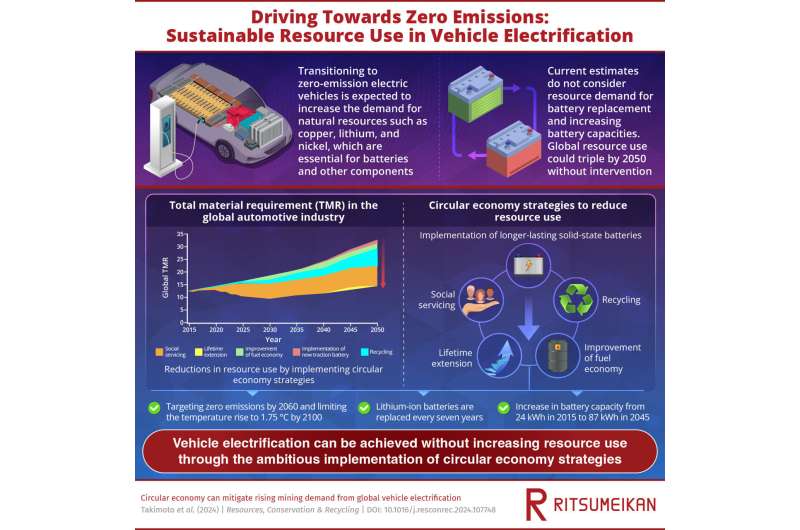

Batteries, which account for 50% of all resources consumed in BEV production, require several minerals such as lithium, nickel, cobalt, manganese, and graphite. However, current estimates of resource demand underestimate total mineral demand as they do not account for battery replacement during the vehicle's lifetime and increasing battery capacities.

In a study published online in the journal Resources, Conservation and Recycling on 5 June 2024, researchers led by Associate Professor Shoki Kosai from Ritsumeikan University, Japan, provide a more realistic estimate of the resource needs for EVs by 2050.

Their research addresses the current underestimations by accounting for raw material demand to produce, operate and maintain EVs. Additionally, they also introduce several strategies to mitigate resource consumption.

This research was co-authored by Mr. Hibiki Takimoto from Ritsumeikan University, Dr. Takuma Watari from the National Institute for Environmental Studies, and Professor Eiji Yamasue from Ritsumeikan University.

"In our study, we seek to address critical questions such as 'To what extent will vehicle electrification contribute to an escalation in resource use?' 'What are the underlying factors driving this change?' and 'To what extent can the increase in resource use be effectively managed and mitigated?'" says Dr. Kosai.

The study assessed the total material requirement (TMR) for EV batteries under three scenarios: the Reference Technology Scenario (RTS), maintaining current energy and technological trends; the 2-Degree Scenario (2DS), requiring major climate change mitigation to limit temperature rise to 2°C; and the Beyond 2-Degree Scenario (B2DS), targeting zero emissions by 2060 and limiting temperature rise to 1.75°C by 2100.

TMR serves as the benchmark for assessing resource use, encompassing both materials directly used in battery manufacturing and those extracted but not utilized. The study assumes vehicles have a lifespan of 15 years or 100,000 km, utilizing lithium-ion batteries with nickel, cobalt, and manganese, replaced every seven years.

The findings reveal that TMR for EVs increases in all three scenarios. Under the RTS scenario, which assumes most vehicles remain internal combustion engine vehicles (ICEVs), the demand for raw materials nearly doubles from 2015 levels.

In the B2DS scenario, where BEVs dominate, the demand is 22.7% higher. In this scenario, lithium-ion batteries are projected to account for 55% of the total resource use in the automotive industry, driven by the production and maintenance of BEVs.

The researchers discovered that implementing specific circular economy strategies could halve resource demand or maintain it at 2015 levels. These strategies include extending vehicle lifetimes, promoting car and ride-sharing services, enhancing material recovery and recycling in new vehicles, improving fuel efficiency, and adopting longer-lasting solid-state batteries.

Among these strategies, ride-sharing and recycling had the greatest impact, reducing resource demand by 37.0%–43.0% and 33.0%–39.6%, respectively. Improvements in fuel economy were also significant, especially for ICEVs, contributing to a reduction in resource demand by 10.2%–21.8%.

Switching to solid-state batteries was another important contributor to reducing resource demand. Solid-state batteries require fewer materials than traditional lithium-ion batteries and do not need to be replaced as often. They reduced the need for additional resources by 30.6% for increasing battery capacity and 29.1% for battery replacement.

With EV demand expected to grow from less than 45 million in 2023 to 250 million in 2030 and reach 525 million in 2035, the implementation of circular economy strategies will be crucial to meet resource demands for future electrification goals.

"Overall, the findings of this study were clear. In the automotive sector, electrification contributes to an increase in resource use by approximately more than twice. Vehicle electrification can be achieved without increasing resource use if a set of circular economy strategies is concurrently and ambitiously implemented," Dr. Kosai.

More information: Hibiki Takimoto et al, Circular economy can mitigate rising mining demand from global vehicle electrification, Resources, Conservation and Recycling (2024). DOI: 10.1016/j.resconrec.2024.107748