This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

proofread

Estimating the environmental impacts of the global lithium-ion battery supply chain

Decarbonization of the global economy will require the production of a large number of batteries for electric vehicles (EVs). However, these batteries require energy and an array of minerals to produce and are not without their own environmental impacts.

Fanran Meng and colleagues trace the energy consumption and greenhouse gas emissions in the global productions and supply chains of two common battery technologies as well as their future variants: nickel-manganese-cobalt (NMC) and lithium-iron-phosphate (LFP). The research is published in the journal PNAS Nexus.

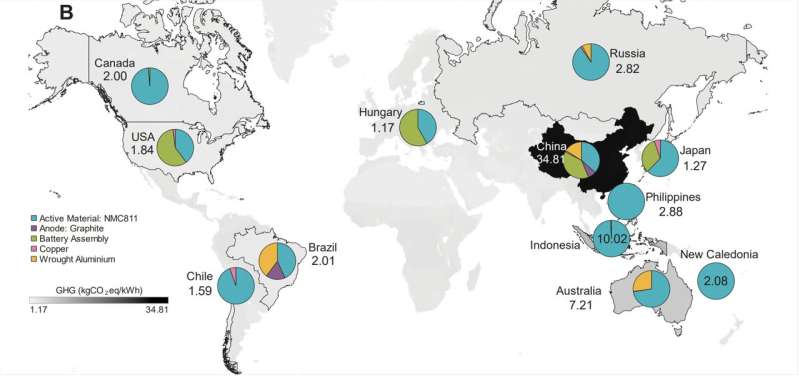

Today, two-thirds of battery-related emissions occur in China (45%), Indonesia (13%), and Australia (9%), in part due to emissions-intensive electricity for nickel mining in Indonesia and nickel refining in China. With the projected growth in EVs, the annual emissions from the EV battery industry globally could exceed 600 MtCO2eq by 2050, which is approximately the annual combustion-based CO2 emitted by Indonesia today, the fourth most populous country in the world.

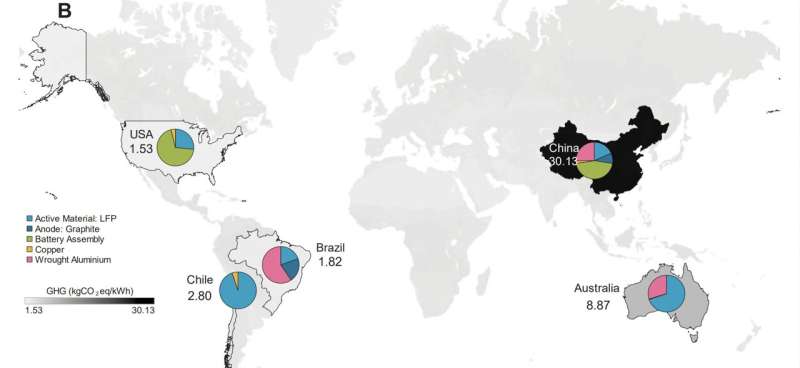

Shifting to less CO2-intensive battery chemistry, like LFP, could reduce emissions by about 20% by 2050. Notably, the patent on LFP batteries expired in 2022, heralding a possible expansion of their use outside of China, where LFP batteries currently dominate the market.

The use of renewable electricity offers a significant CO2 reduction prospect, given that electricity consumption accounts for about 37% of total battery manufacturing emissions. Over time, with the creation of a circular battery recycling economy, manufacturers could rely increasingly on secondary materials, thus reducing demand for emissions-intensive, newly mined primary materials.

The authors add that breakthroughs in battery chemistries such as lithium-sulfur, lithium-silicon, lithium-air, solid-state, and sodium-ion batteries could potentially pave the way to a more sustainable battery future.

More information: Jorge A Llamas-Orozco et al, Estimating the environmental impacts of global lithium-ion battery supply chain: A temporal, geographical, and technological perspective, PNAS Nexus (2023). DOI: 10.1093/pnasnexus/pgad361