May 15, 2018 report

Implantable sensor decomposes when its usefulness ends

A team of researchers based at Stanford University has developed a new kind of implantable strain and pressure sensor that decomposes harmlessly when its usefulness ends. In their paper published in the journal Nature, the group describes developing and testing their sensor. Sung-Geun Choi and Seung-Kyun Kang with Korea Advanced Institute of Science and Technology offer a News & Views piece on the work done by the team at Stanford in the same journal issue.

As most people know, the standard procedure for recovery from orthopedic surgery is physical rehabilitation. But knowing how much stress or pressure repaired parts can withstand is still more art than science. For that reason, scientists have been looking for ways to implant sensors that will give a more accurate measure of what is going on inside the body during rehab. Ideally, such sensors would simply disappear once they are no longer needed—otherwise, a second surgery would be necessary to remove them. But until now, such sensors have suffered from performance issues or were not wholly biocompatible. In this new effort, the team at Stanford reports that their new sensor overcomes both issues.

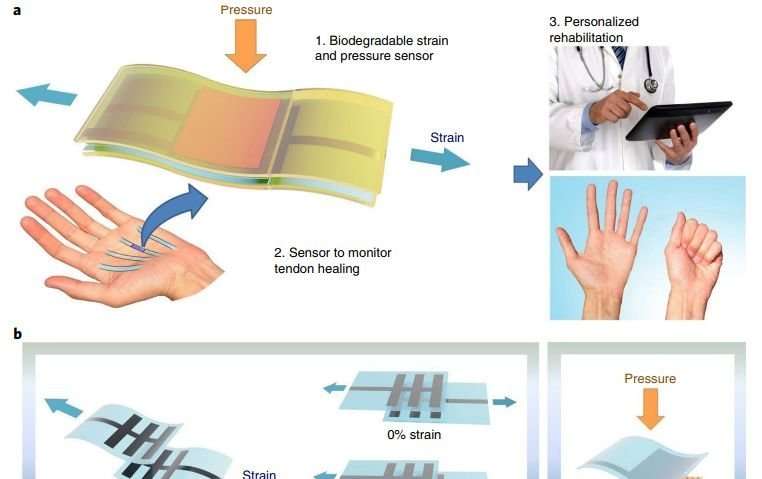

The sensor structure was made by stacking two sensors, one for measuring strain, the other for pressure—it was made from two types of biocompatible and biodegradable polymers and also features magnesium electrodes. The final product involved five layers of material including top and bottom packaging, covering the sensors. The team tested the sensor by implanting it in the back of a rat.

The team reports that the sensor was capable of measuring strains as small as 0.4 percent and pressures as small as 12 Pa. In addition, other than a small amount of initial inflammation, they observed no ill effects in the rat. They report also that they were able to set the amount of time before decomposition by mixing the ingredients when making the sensor structure. As a bonus, they noted that the sensor operated normally during the decomposition period, and only ceased when it was no longer useful. Furthermore, they report that decomposition of the sensor did not cause any problems for the rat.

More information: Clementine M. Boutry et al. A stretchable and biodegradable strain and pressure sensor for orthopaedic application, Nature Electronics (2018). DOI: 10.1038/s41928-018-0071-7

Abstract

The ability to monitor, in real time, the mechanical forces on tendons after surgical repair could allow personalized rehabilitation programmes to be developed for recovering patients. However, the development of devices capable of such measurements has been hindered by the strict requirements of biocompatible materials and the need for sensors with satisfactory performance. Here we report an implantable pressure and strain sensor made entirely of biodegradable materials. The sensor is designed to degrade after its useful lifetime, eliminating the need for a second surgery to remove the device. It can measure strain and pressure independently using two vertically isolated sensors capable of discriminating strain as small as 0.4% and the pressure exerted by a grain of salt (12 Pa), without them interfering with one another. The device has minimal hysteresis, a response time in the millisecond range, and an excellent cycling stability for strain and pressure sensing, respectively. We have incorporated a biodegradable elastomer optimized to improve the strain cycling performances by 54%. An in vivo study shows that the sensor exhibits excellent biocompatibility and function in a rat model, illustrating the potential applicability of the device to the real-time monitoring of tendon healing.

© 2018 Tech Xplore