New combustion models improve efficiency and accuracy

Researchers at Princeton University have developed a new model that will allow engineers to accurately predict the characteristics of combustion processes with far less computing power than previously needed. The new model breaks a long-standing trade-off between models that are efficient but narrowly useful and models that are more general but computationally expensive.

Engineers rely on simulations to design more efficient and lower-emission engines, gas turbines, and rockets or to predict the spread of fires. Until now, they had two options to predict of fuels will burn in these situations. They could use models that were accurate but so costly to run that they were impractical for many uses. Or, they could use combustion models that were faster and cheaper but usually far less helpful because they required engineers to know all of the details about the combustion system before even running the simulations.

"Those were the only models," said Michael Mueller, an associate professor of mechanical and aerospace engineering at Princeton University.

Now Mueller's research team has developed a new approach to modeling combustion that combines the rigor and generality of the computationally expensive models with the computational speed and efficiency of the simplified models.

In two papers published in the Proceedings of the Combustion Institute, Mueller's team described their new approach to modeling combustion. Cristian Lacey, a graduate student in Mueller's lab and a co-author of the papers, said the work is a combination of not only the improved combustion model but also a completely new approach to how the model is implemented in the combustion simulation software.

Lacey explained that computationally expensive models work by solving equations for all groups of chemicals (called chemical species) in the combustion. Often these run to thousands of equations, which make the simulations extremely computationally intensive, with a typical simulation often requiring days or weeks of time on thousands of processors.

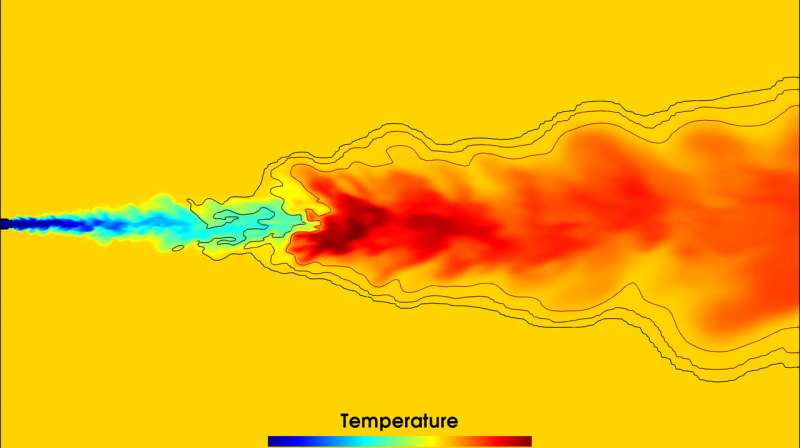

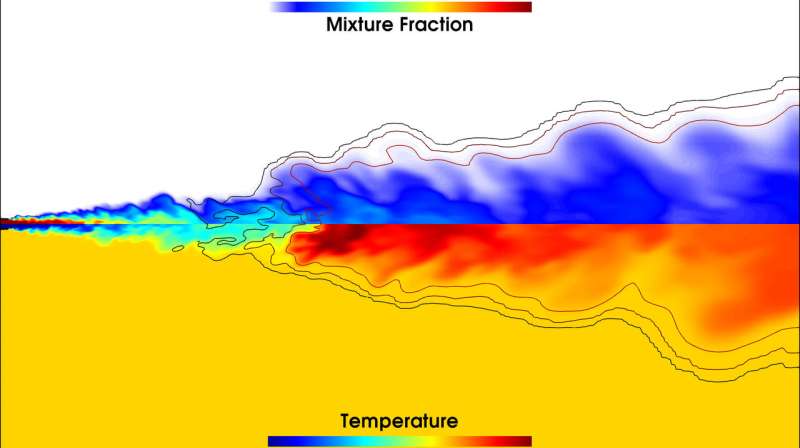

"But, instead, the evolution of these chemical species can be collapsed onto just a few variables," Lacey said. "The challenge is to identify these variables and how the detailed chemical composition depends on these variables, something we refer to as a 'manifold'."

By solving equations only for these few variables along with the turbulent flow of gasses during combustion, the simulations are much more computationally efficient. Instead of weeks on thousands of processors, ideally the new simulation can run overnight on tens of processors. The new system also does not require engineers to specify some details about how the fuels are composed. The traditional approaches require users to specify whether the fuel and oxidizer are completely mixed at the outset of combustion (called premixed combustion) or whether the combustion is controlled by the mixing of oxidizer and combustion (non-premixed.)

The team further increased speed by adopting a new computational strategy for the simulations. Conventional models operate by computing relationships among variables and storing the results in memory before running the simulations themselves. Instead of storing similar information in memory, Mueller's team developed a method in which the relationships are only computed as needed and stored in a flexible data structure. The method, which Mueller called light machine learning, slashed the computational demands without sacrificing the simulations accuracy.

Mueller said that this work is only the first step to prove the utility of the overall modeling framework and that the team is continuing to validate the model—check its accuracy against experimental measurements—over a wide array of combustion problems. Even at this early stage, Mueller says that the interest from both industry and government has been very intense with the ultimate aim to implement this model into software in regular use by combustion engineers.

More information: Alex G. Novoselov et al. Large Eddy Simulation of a turbulent lifted flame using multi-modal manifold-based models: Feasibility and interpretability, Proceedings of the Combustion Institute (2020). DOI: 10.1016/j.proci.2020.06.217

Cristian E. Lacey et al. In-Situ Adaptive Manifolds: Enabling computationally efficient simulations of complex turbulent reacting flows, Proceedings of the Combustion Institute (2020). DOI: 10.1016/j.proci.2020.06.207