New insights into 3-D printing of spacers and membranes for water treatment

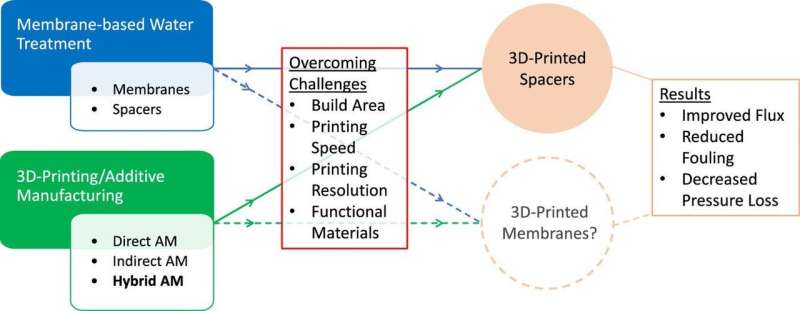

3-D printing has seen great advancements in various aspects over the past few decades, and many industries have witnessed innovative breakthroughs in their respective fields. Amongst them, the water treatment industry in particular has reaped the benefits of 3-D printing. High performance spacers and membranes can be fabricated by 3-D printing technologies, and they help increase production while minimizing energy consumption in purification processes.

Researchers from Nanyang Technological University (NTU) and the Singapore University of Technology and Design (SUTD) reviewed the recent efforts and shortcomings as well as the conflicting reports of 3-D printing in membrane-based water treatment. Their research paper entitled "A review on spacers and membranes: Conventional or hybrid additive manufacturing?" has been published in Water Research.

In the paper, they discussed the potential of 3-D printed spacers. The great freedom of design in 3-D printing enables the fabrication of complex and innovative spacers, which was previously impossible with conventional heat extrusion methods. These spacers were able to reduce the number of dead zones within flow channels, and help mitigate detrimental membrane fouling problems. Some spacer designs such as the helical spacer, turbospacer, and column spacer were even able to reduce energy consumption.

An interesting perspective was also presented in the paper regarding the feasibility of 3-D printed membranes. Microfiltration membranes (MF) with pore sizes < 1 μm were previously fabricated by conventional processes such as sintering or phase inversion. However, for 3-D printing, the Two-Photon Polymerization printing technique is said to have the finest printing resolution of about 1 μm to date. Theoretically, it should be impossible to fabricate microfiltration (MF) membranes with 3-D printing. It has thus sparked much confusion in the water treatment industry when an increasing number of publications have reported the successful fabrication of 3-D printed MF membranes over the past decade.

In an attempt to resolve this confusion, the paper critically analyzes these 3-D printed membranes, especially with regard to 3-D printing's role in the overall fabrication process. Hybrid additive manufacturing, a process where 3-D printing is used in conjunction with other established fabrication methods, is also introduced in the paper. It shows how 3-D printing can still be a powerful tool in the fabrication of membranes when used together with other established processes despite its inadequate printing resolution.

"3-D printing is gradually evolving from a single-standalone process to a multi-integrated process. The application continues to grow in the water treatment industry, especially the membrane-based technologies. Future focus is expected to shift from lab scale prototyping to large scale manufacturing," said principal investigator Associate Professor Chong Tzyy Haur from NTU.

"It will be a challenge to overcome upscaling and material limitations, but consistent research efforts are already evident today. Potentially, 4-D printing can even be a possibility in the future to fabricate smart spacers and membranes that adapt to their surrounding environment," explained co-author Professor Chua Chee Kai from SUTD.

More information: Jing Wee Koo et al, A review on spacers and membranes: Conventional or hybrid additive manufacturing?, Water Research (2020). DOI: 10.1016/j.watres.2020.116497