This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

proofread

Protecting lithium metal anodes to enable long cycling practical Li-S batteries

Within construction of long-cycling practical lithium sulfur (Li-S) batteries, the protection of the Li metal anode is a primary focus. Rapidly growing attention is being paid to the protection of the Li metal anode in working Li-S batteries, with essential improvement in battery performances in recent years. Considering the importance and the great progress of this field, a timely review was needed to summarize the current understanding. Recent advances of Li metal anode protection in Li-S batteries has been presented by Jia-Qi Huang of the Beijing Institute of Technology and his research team.

They published their work on Jan. 10 in Energy Material Advances.

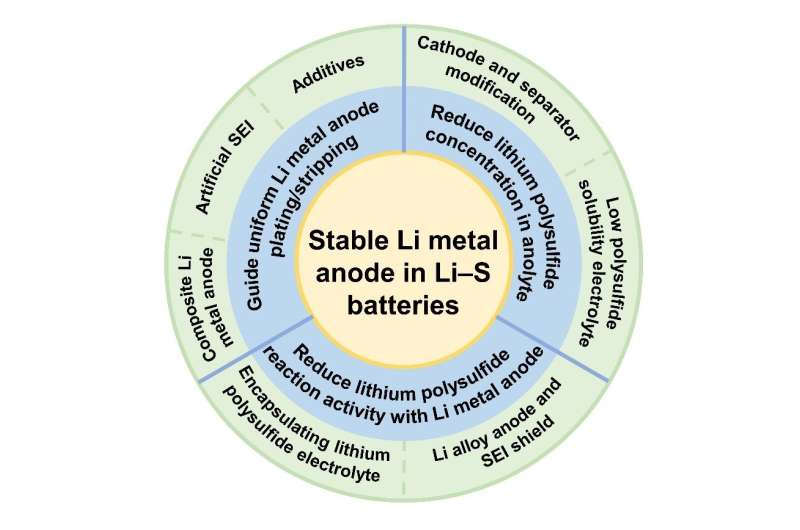

"From the perspective of the challenges faced by Li metal anode in Li-S batteries, we proposed three protection strategies in general." Huang said. "The first strategy is guiding uniform Li plating/stripping, the second strategy is reducing polysulfide concentration in anolyte, and the third strategy is reducing polysulfide reaction activity with Li metal anodes."

To guide uniform Li metal anode plating/stripping, three strategies were introduced regarding constructing a composite Li metal anode, introducing robust artificial solid electrolyte interphase, and introducing electrolyte additives. To reduce polysulfide concentration in anolyte, two main strategies were introduced regrading suppressing the diffusion of lithium polysulfides out of the catholyte and reducing the solubility of lithium polysulfides in electrolyte. To reduce polysulfide reaction activity with Li metal anodes, two strategies were introduced through lithium polysulfide encapsulating and reducing the self-activity of Li metal by Li-based alloy or constructing a shielding interphase.

"Energy storage technologies represented by rechargeable batteries are regarded as an indispensable part of the modern energy system based on renewable yet intermittent energy sources," said Huang, a study author and professor of Advanced Research Institute of Multidisciplinary Science, Beijing Institute of Technology. "Advanced battery systems with high energy density are of great importance to fill the blank for future applications."

Huang and his research team have focused on Li-S battery, which has a high theoretical energy density of 2600 Wh kg−1 and is widely considered as one of the most promising next-generation battery technologies.

"Li-S batteries employ elemental sulfur as the cathode active material, Li metal as the anode, and ether-based electrolyte for ion transportation and conversion of the sulfur species," Huang said. "Nowadays, the electrochemical performances of the sulfur cathode have achieved great promotion. High discharge specific capacity and stable cycling of the sulfur cathode can be achieved under high-loading conditions."

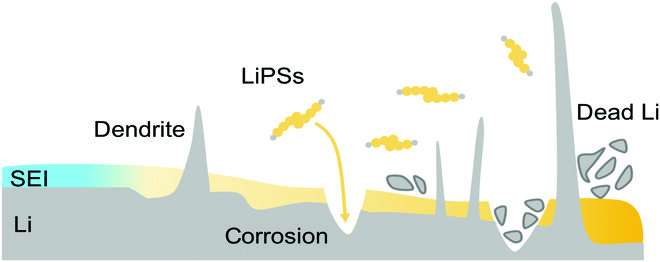

However, the practical application of Li-S batteries is hindered by the poor cycling stability. According to Huang, Li metal is the bottleneck that limits the cycling lifespan of practical Li-S batteries. Under practical working conditions, high-areal-capacity sulfur cathode and limited anode excess aggravate uneven Li stripping and plating to produce massive Li dendrites and inactive Li that result in rapid failure of Li metal anode. Moreover, the soluble high-order lithium polysulfides generated from the cathode side diffuse to the Li anode side and chemically react with Li metal, leading to the reduction of Coulombic efficiency, severe Li metal corrosion, and the depletion of active Li as well as exacerbation of the Li anode unevenness.

"Although the stability of Li metal anode in Li-S batteries has been significantly improved, there is still a long way to go before practical battery application," Huang said. "Focusing on the main challenges and the current protecting strategies, it is believed that essential progress will be made in this research frontier and practical application of advanced Li-S batteries will be realized in the near future."

To inspire future research and development of constructing advanced Li metal anode for Li-S batteries, Huang and his team also pointed out that the currently proposed protection strategies should be tested in practical Li-S batteries under working conditions, that the Li metal anode/electrolyte interfacial behaviors must be further understood, and the balance of both the sulfur cathode and the Li metal anode performances is necessary to consider.

More information: Chen-Xi Bi et al, Protecting lithium metal anodes in lithium-sulfur batteries: A review, Energy Material Advances (2023). DOI: 10.34133/energymatadv.0010