This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Researchers hope to prevent catastrophes with next-generation sensors

As the wind and rain pound the blades of a wind turbine, UBC Okanagan researchers carefully monitor screens hundreds of kilometers away, analyzing whether the blades' coatings can withstand the onslaught. While this was only a test in a lab, the researchers are working to improve the way structures such as turbines, helicopter propellers and even bridges are monitored for wear and tear from the weather.

A changing climate is increasing the need for better erosion-corrosion monitoring in a wide range of industries from aviation to marine transportation and from renewable energy generation to construction, explains UBC Okanagan doctoral student Vishal Balasubramanian.

In many industries, wear-resistant coatings are used to protect a structure from erosive wear. However, these coatings have a limited service life and can wear out with time. As a result, these coated structures are periodically inspected for abrasion and breaches, which are then fixed by recoating the damaged areas.

Currently, these inspections are done manually using a probe, and Balasubramanian—one of several researchers working in UBC's Okanagan Microelectronics and Gigahertz Applications (OMEGA) lab—is working to develop sensors that can be embedded directly into the coatings.

This could take away any chance of human-caused errors and drastically reduce the inspection time. By integrating artificial intelligence (AI) and augmented reality (AR) into these embedded sensors, the researchers can monitor in real-time the wear and tear of protective mechanical coatings designed to prevent catastrophic failures.

"By leveraging AI technologies into our microwave resonator sensors, we're able to detect not only surface-level coating erosion but we can also distinguish when an individual layer is being eroded within a multi-layer coating," explains Balasubramanian, lead author of research recently published in Nature Communications.

Some studies suggest that metal corrosion in the United States has a cost of nearly $300 billion a year; more than 3% of that country's gross domestic product. But it's not just about money.

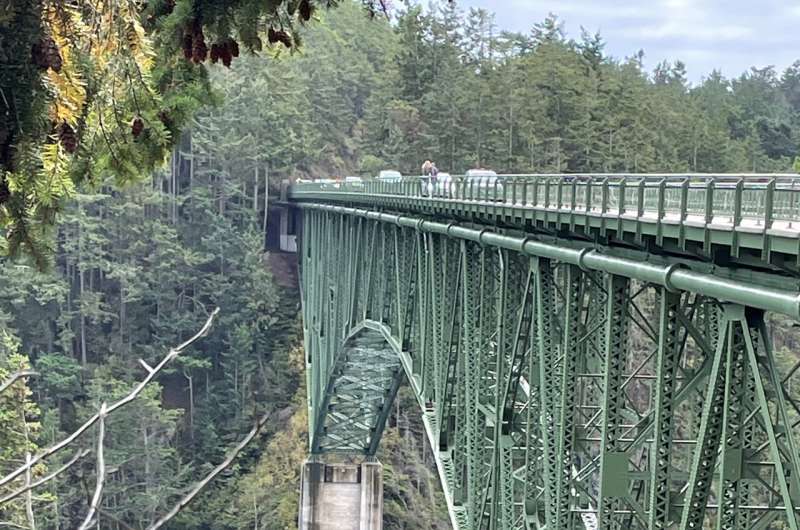

Erosion can cause irreversible damage to the exterior surfaces of bridges, aircraft, cars and naval infrastructure, explains Balasubramanian. History has a long list of disasters where erosion was identified as the primary reason for structural failures that have led to the loss of thousands of lives—including the 2018 Genoa bridge collapse in Italy, the 1984 Bhopal gas tragedy in India and the 2000 Carlsbad gas pipeline fire in Texas.

"Being able to proactively monitor and address equipment degradation—especially in harsh environments—can undoubtedly safeguard important infrastructure and reduce the effect on human life," says Dr. Mohammad Zarifi, an Associate Professor in UBCO's School of Engineering and principal investigator at the OMEGA Lab, adding, "For several years, we've been developing microwave-based sensors for ice detection and the addition of newer technologies like AI and AR can improve these sensors' effectiveness exponentially."

The newly developed sensors can detect and locate the eroding layer in multi-layered coatings and can also detect the total wear depth of protective coatings. This information is collected and can provide a detailed understanding for engineers and stakeholders of the potential damage and danger of failures.

In the lab, the differential network device interface system was tested at varying temperatures—extreme hot and cold—and different levels of humidity and UV exposure to mimic several harsh environments. The developed system was tested with different types of coatings and its response was monitored in four different types of experimental setups that performed the desired environmental parameter variations.

"We tested our sensors under some of the harshest environments including various temperatures, humidity and UV exposures," says Balasubramanian. "We continue to push the limits of what these sensors are able to withstand in order to stay ahead of what's transpiring around the world."

For his work, Balasubramanian was recently recognized with an Award for Excellence in Microsystems CAD Tool & Design Methodology by CMC Microsystems. The award recognizes a graduate student who demonstrates a novel design technology advancement with the most potential for applicable improvements to microsystems manufacture and deployment.

More information: Vishal Balasubramanian et al, Non-destructive erosive wear monitoring of multi-layer coatings using AI-enabled differential split ring resonator based system, Nature Communications (2023). DOI: 10.1038/s41467-023-40636-9