October 10, 2023 feature

This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

preprint

trusted source

proofread

A human-inspired robotic hand based on a modular structure

In recent years, roboticists have developed increasingly sophisticated robotic systems designed to mimic both the structure and function of the human body. This work includes robotic hands, grippers that allow robots to grasp objects and manipulate them like humans do while completing everyday tasks.

Ideally, robotic hands should be able to perform highly precise movements, while also being relatively affordable and easy to fabricate. However, most bio-inspired skeleton structures for robotic hands introduced so far have highly intricate designs containing numerous advanced components, which makes them difficult to fabricate on a large scale.

Researchers at Massachusetts Institute of Technology (MIT) recently created a new highly precise robotic hand that could be easier to upscale, as its components can be crafted using commonly employed techniques, such as 3D printing and laser cutting. Their robotic hand, introduced in a paper published in the journal 2023 IEEE International Conference on Soft Robotics (RoboSoft), is based on a so-called modular structure, meaning that it comprises multiple building blocks that can be rearranged to achieve different movements.

"While parallel grippers and multi-fingered robotic hands are well developed and commonly used in structured settings, it remains a challenge in robotics to design a highly articulated robotic hand that can be comparable to human hands to handle various daily manipulation and grasping tasks," Chao Liu, Andrea Moncada and their colleagues wrote in their paper.

"Dexterity usually requires more actuators but also leads to a more sophisticated mechanism design and is more expensive to fabricate and maintain. Soft materials are able to provide compliance and safety when interacting with the physical world but are hard to model."

The primary objective of the recent work by Liu, Moncada and their collaborators was to create a flexible robotic hand that does not require particularly sophisticated and expensive components. This flexible hand, however, should still be able to perform more advanced movements than robotic grippers that are solely based on rigid materials, ultimately advancing the object manipulation skills of robots.

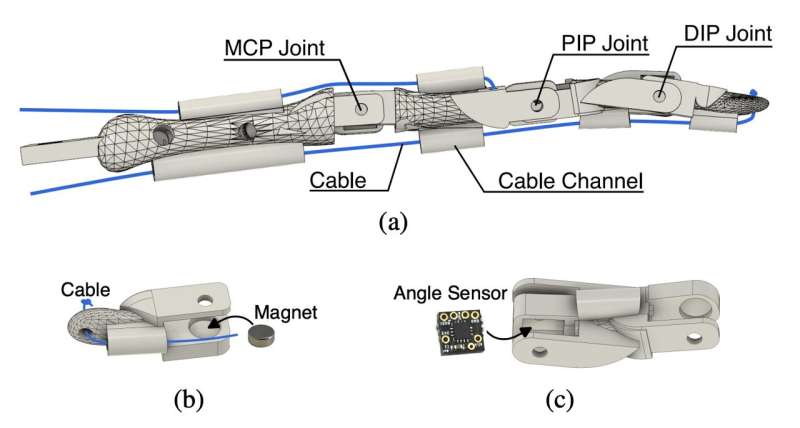

"This work presents a hybrid bio-inspired robotic hand that combines soft matters and rigid elements," Liu, Moncada and their colleagues wrote. "Sensing is integrated into the rigid bodies resulting in a simple way for pose estimation with high sensitivity."

The modular robotic hand created by the research team at MIT can easily be adapted to best suit different applications. For instance, researchers can choose to add or remove fingers and arrange its components differently to achieve distinct grasp types or boost its performance in specific scenarios.

"The proposed hand is in a modular structure allowing for rapid fabrication and programming," the researchers wrote. "The fabrication process is carefully designed so that a full hand can be made with low-cost materials and assembled in an efficient manner."

Remarkably, both the rigid and soft components used to create the new robotic hand are easy to fabricate. The 'bones' that make up the hand's skeleton can be 3D printed, while magnets, sensors, and cables contained inside it are readily available on the market.

To create the skin that goes around the bones, the team used a simple two-step molding process. They first created different mold pieces using 3D printing and then used these pieces to mold silicone into the shape of the fingers.

As part of their study, Liu, Monada and their colleagues created a prototype of their hand with five fingers and evaluated its performance. They found that the hand could successfully perform different types of grasps, replicating the way in which human hands grab and hold various objects. Their robotic hand was able to robustly grasps various flexible and rigid objects of different sizes, including a plastic cup, a pen and a round plastic ring.

The robotic hand could soon be developed and tested further, to enhance and validate its capabilities. Eventually, it could be integrated with other robotic limbs to create scalable humanoid robots that are better at manipulating objects.

"Future work includes a palm design with an additional rotation DoF for the thumb, a compact design of the wrist to hold the electronics, and the development of the control strategy for dexterous manipulation and grasping," the researchers conclude in their paper.

More information: Chao Liu et al, A Modular Bio-inspired Robotic Hand with High Sensitivity, 2023 IEEE International Conference on Soft Robotics (RoboSoft) (2023). DOI: 10.1109/RoboSoft55895.2023.10121946. On arXiv: DOI: 10.48550/arxiv.2309.16081

© 2023 Science X Network