This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Tiny memory cell withstands extreme temperatures, enables smaller and better semiconductors for microelectronics

Materials scientists at Kiel University and the Fraunhofer Institute for Silicon Technology in Itzehoe (ISIT) have cleared another hurdle in the development and structuring of new materials for next-generation semiconductor devices, such as novel memory cells.

They have shown that ferroelectric aluminum scandium nitride can be scaled down to a few nanometers and can store different states, making it suitable as a nanoswitch. In addition, they have proved aluminum scandium nitride to be a particularly stable and powerful semiconductor material for current technologies based on silicon, silicon carbide and gallium nitride. In contrast to today's microelectronics, the material can withstand extreme temperatures of up to 1,000°C.

This opens up applications such as information storage or sensors for combustion processes in engines or turbines in both the chemical industry and in the steel industry. The results were published in the journal Advanced Science. The study was part of a research project that brings together basic research in materials development and applications in microelectronics.

Usable for applications for the first time

Today, high-performance chips and microelectronic components can be found in every computer, car and industrial plant. Stable and energy-efficient microelectronics are the technical basis for the digitalization of industry and society, a sustainable energy supply, or modern medical technology. But today's computer chips operate on very low voltages of just 1–2 volts—at higher voltages they would break down.

Fichtner and his colleagues were able to produce the material as a film just 4 to 5 nanometers thick, reducing the voltage required from the original more than 100 volts to 1 volt. "In our study, we were able to show for the first time that aluminum scandium nitride also works in these small dimensions without changing its properties," says Dr. Simon Fichtner, materials scientist at Kiel University and ISIT. "So it works on standard silicon chips and is therefore very well suited as a semiconductor material."

Aluminum scandium nitride can now be used to produce components that are just a few nanometers in size and can be integrated into existing semiconductor technology. "This means that we are leaving basic research behind and can really think about applications for the first time," says Dr. Niklas Wolff from the Collaborative Research Center 1261 "Magnetoelectric Sensors" at Kiel University. The interdisciplinary research network is already using the material in sensor prototypes for medical diagnostics.

More stable than previous silicon storage systems

As part of the BMBF project "SALSA," the materials researchers were also able to show that memory cells made of aluminum scandium nitride are significantly more stable than the silicon memories used to date. "Our memory cells retained their information in tests at 1,000°C. Silicon memories available today only work up to a maximum of 150°," says Fichtner. This makes it possible to use them under extreme conditions, such as those found in many industrial production processes.

In his doctoral thesis at the CAU four years ago, Fichtner was the first to show that aluminum scandium nitride belongs to the group of ferroelectric materials, which attracted great interest in the international research community. In ferroelectrics, electrical dipoles (polarization + / -) are permanently aligned without the need for an external electrical field—similar to a refrigerator magnet. When an electric voltage is applied, the crystal structure of the material at the atomic level is reversed, and so is its electrical orientation.

The electrical properties of these materials can therefore be changed in a controlled way from the outside, they can be "switched" between two states. This makes them very interesting for industrial applications, but so far they have not been powerful enough or too unreliable. The fact that aluminum scandium nitride works at high temperatures and with a voltage of just one volt are clear advantages over conventional ferroelectric materials.

Arrangement of the atoms changes

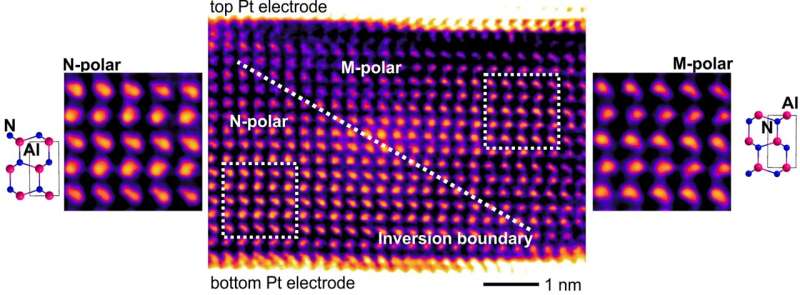

In their study, the research team also showed for the first time exactly what happens in aluminum scandium nitride during the switching process. They used a scanning transmission electron microscope to analyze the atomic structure of the material on the nanometer scale. They were able to show that the arrangement of the nitrogen and aluminum atoms changes after the voltage is applied.

"Surprisingly, this does not happen everywhere in the material at the same time, as in some other ferroelectric materials, but rather smoothly, in individual areas one after the other," says Wolff. In other words, the material does not switch all at once.

"If you consider that our current storage technologies work with the two states 0 and 1, other intermediate states and completely different applications might be possible," adds doctoral researcher Georg Schönweger.

"The connectivity to existing technologies opens up a wide range of possible applications, including power electronics that are based entirely on gallium nitride semiconductors, high-frequency technology or more energy-efficient computer architectures," says Prof. Hermann Kohlstedt, spokesman for the Collaborative Research Center 1461 "Neurotronics." Here, the use of aluminum scandium nitride for innovative neuromorphic computers based on the human brain is being researched.

As part of the BMBF project, Fraunhofer ISIT is investigating its use for actuators, for example in loudspeakers, and has already developed prototypes for this purpose. The Fraunhofer Institute for Applied Solid State Physics in Freiburg (IAF) is working on the integration of ferroelectric thin films made of aluminum scandium nitride in the production of better transistors.

More information: Georg Schönweger et al, In‐Grain Ferroelectric Switching in Sub‐5 nm Thin Al0.74Sc0.26N Films at 1 V, Advanced Science (2023). DOI: 10.1002/advs.202302296