This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

trusted source

proofread

New telerobotic system for hazardous waste clean-up successfully demonstrated

Because they can go where humans can't, robots are especially uniquely suited for safely working with hazardous nuclear waste. But first, those robots need to become like the humans they are replacing, with arms and fingers that can closely mimic the movements of a person.

Now, scientists at the U.S. Department of Energy's (DOE) Argonne National Laboratory have designed and tested a remote-controlled, dual-arm telerobotics system with human-like capabilities that have the potential to revolutionize hazardous waste clean-up and hold potential for broader applications.

Designed as part of a multilaboratory, multi-institution project, the telerobotics system was recently successfully tested in a mock, nonradioactive setting at DOE's Oak Ridge National Laboratory (ORNL). Along with Argonne and ORNL, the Oak Ridge Office of Environmental Management (OREM), the University of Illinois Chicago (UIC), Northwestern University, and United Cleanup Oak Ridge, LLC (UCOR) are collaborators on the three-year project launched in 2023.

The technology is still in the prototype stage. The long-term goal is to use collaborative robots, or "cobots," and emerging digital technologies to help clean up nuclear waste in dormant nuclear facilities overseen by DOE's Office of Emergency Management. The technology also has potential for uses beyond DOE nuclear waste sites.

Demonstration proved robot capability, offered training

In the nuclear industry, hot cells and glovebox systems were, for decades, the traditional method for handling radioactive materials. Hot cells are heavily shielded concrete cells with mechanical manipulators to handle highly radioactive materials.

Similarly, remote operators can also use tong-like manipulators to move the materials within the hot cell. A glove box is a securely sealed container found inside the hot cell, with openings that allow laboratory operators to access attached gloves to maneuver and study hazardous materials.

However, these systems are no longer useful since they rely on obsolete, manually operated technology and cannot be moved to task sites. Argonne's mobile robotic hot cell system, which can easily be deployed on-site, would essentially robotize the current method.

The recent demonstration of the Argonne-designed robot was held at a long-closed ORNL radiochemical processing facility that houses diverse radiochemical waste materials.

In the demonstration, the goal was to use telerobotic technology to handle the mock nuclear waste canisters contained in a hot cell within the ORNL facility. The material in the canisters is listed by DOE as containing radioactive materials. Equipped with remarkably dexterous, multi-fingered arms, the robots successfully opened the mock nuclear waste canisters, inspected and sorted their contents, and closed the containers.

During the weeklong demonstration, team members received hands-on training to perform specific tasks, such as manipulating the robot's arms to open a plastic bottle.

The telerobotics technology marks an important step in improving the safe and effective cleanup of hazardous materials at nuclear sites, said the system's designer, Young Soo Park, who leads Argonne's Robotics and Remote Systems Program in the Applied Materials division.

"Along with Argonne, the entire robotics community has been developing innovative new robotics technologies. But there have been very few actual demonstrations of the telerobotic system's capabilities," Park said. "The highly successful demonstration [at ORNL] proved the technical feasibility of this first-of-a-kind concept implementing a complex, dexterous, telerobotic system for practical applications."

Drawing on decades of expertise in robotics, Argonne scientists developed the telerobotic system in just six months at Argonne's Robotic and Augmented Reality Lab. In late 2023, the technology was transported to ORNL for integration with the lab's mobile work cell systems.

The new robotics system runs on Argonne's mixed-reality digital twin software platform. The system integrates virtual models, sensory displays, and hardware control technology. Digital twin technology acts as a bridge between the real and virtual worlds, creating a digital replica, or twin, of a physical object. The digital twin supports optimization in all phases of the remote operation system, including design, training operation, and analysis.

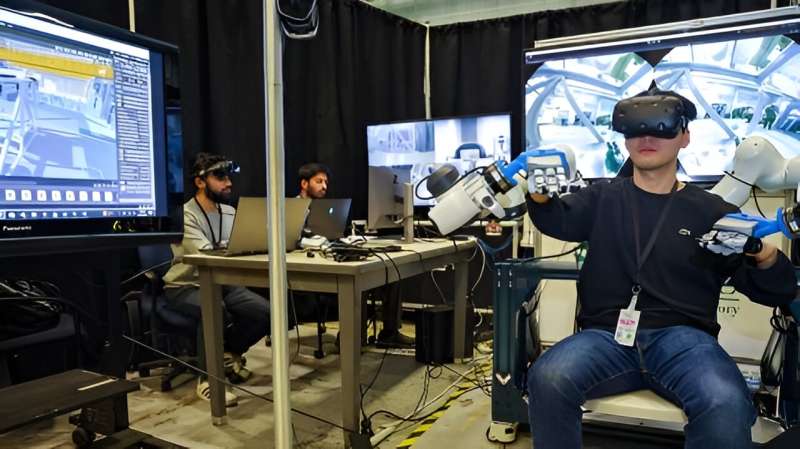

Seated at a digital workstation, operators equipped with a virtual reality headset and touch-sensitive haptic gloves can control the robots physically and virtually at the same time. When the operator moves its arms, the dual-armed robot mimics the movements. The touch-sensitive gloves allow the operator to touch and feel objects in a natural way effectively. Sensors on the gloves provide operators with direct feedback that helps improve the precision and accuracy of the task.

"Our first aim in telerobotic system design is to facilitate a 'telepresence,' to make the operator feel as though they are present within the hot cell, able to manipulate the objects with both hands and to experience multimodal sensory feedback in a direct, natural way," Park said.

Robotic hot cell technology could eventually replace hot cells and glove box systems for a wide variety of hazardous materials handling applications. The mobile telerobotic system can move from one hot cell to the next. Operators can robotically handle, sort, and inspect hazardous waste from a remote location without removing the materials from the cell. "Our mobile, robotic system greatly improves worker safety and efficiency and reduces costs," Park said.

As one of the most advanced avatar systems, the dual-arm telerobotic system has potential for applications outside of the nuclear industry.

"The telerobotic system can be used in applications where a physical telepresence is required," Park said. "Examples include industrial applications such as construction and maintenance of facilities and social service applications such as medical and health care systems. Also, the robotic hot cell can be used to replace hot cells and glove boxes in scientific and industrial applications such as in laboratory experiments and materials processing."

Real-world test of telerobotics system planned this year

The team's diverse expertise and close collaboration are key to the project's success. Each partner is managing one piece of the project scheduled for completion in 2024.

Argonne developed the digital twin software, built the dual-arm robot system, and successfully tested its teleoperation. Northwestern University developed the prototype for dexterous multi-fingered manipulation of the robotic arms. UIC developed the integrated automation system.

ORNL is developing the mobile hot cell structure for remote handling systems. UCOR, the cleanup contractor for DOE's Oak Ridge Reservation, manages environmental safety and health throughout the project. DOE's Office of Emergency Management will oversee progress through completion.

The team is advancing the mobile robotics hot cell technology to prepare for a real-world demonstration later this year. A successful demonstration will pave the way for using the mobile telerobotics system to aid DOE's Environmental Management Office clean-up of 107 nuclear sites. The ORNL complex is one of 15 remaining nuclear sites still undergoing clean-up.