This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

peer-reviewed publication

trusted source

proofread

Are high-purity cathode materials truly necessary? An alternative to reduce secondary battery costs

Manufacturers of secondary battery cells (LG Energy Solution, Samsung SDI, and SK) have been insisting on very stringent purity specifications from suppliers of cathode materials to ensure a consistent quality output.

The purity specifications for cathode materials have been closely guarded as trade secrets, with little active scrutiny on the necessity of such high specifications. In response to the demands of cell manufacturers, suppliers of cathode materials have been investing significantly in purifying raw metals, consequently raising the unit cost of batteries.

A research team has discovered that the purity specifications for cathode materials, as set by cell manufacturers, are overly stringent.

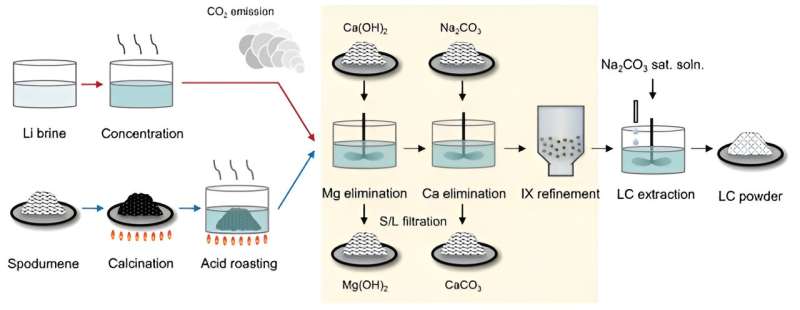

Their research demonstrates that streamlining the lithium refining process could substantially reduce the unit cost of batteries. The research findings are published in Nature Communications.

In this research, the team delved into the impact of lithium raw material purity on the production and performance of secondary battery cathode materials. Conventionally, it's assumed that impurities in lithium materials hamper secondary battery performance. Therefore, the goal is to manufacture lithium materials with purity of at least 99.5%.

Nevertheless, the team uncovered that the presence of approximately 1% magnesium (Mg) impurity in the lithium raw material actually enhances process efficiency and prolongs the secondary battery's lifespan. Through their experiments, they demonstrated that utilizing low-purity lithium, not entirely rid of impurities, could reduce secondary battery production costs and carbon dioxide emissions by up to 19.4% and 9.0%, respectively.

The researchers were led by Professor Yong-Tae Kim from the Department of Materials Science and Engineering at Pohang University of Science and Technology (POSTECH), in collaboration with Professor Kyu-Young Park from the Graduate Institute of Ferrous & Eco Materials Technology and the Department of Materials Science and Engineering at POSTECH, and the research team of Dr. Woochul Jung from the Research Institute of Industrial Science and Technology (RIST).

Professor Kim stated, "Secondary battery cell manufacturers need to reassess whether their current cathode material specifications are too stringent. Considering unconventional approaches could offer a fresh strategy against China's aggressively low prices."

More information: Gogwon Choe et al, Re-evaluation of battery-grade lithium purity toward sustainable batteries, Nature Communications (2024). DOI: 10.1038/s41467-024-44812-3