This article has been reviewed according to Science X's editorial process and policies. Editors have highlighted the following attributes while ensuring the content's credibility:

fact-checked

trusted source

proofread

Combating carbon footprint: Novel reactor system converts carbon dioxide into usable fuel

Reducing carbon emissions from small-scale combustion systems, such as boilers and other industrial equipment, is a key step towards building a more sustainable, carbon-neutral future. Boilers are widely used across various industries for essential processes like heating, steam generation, and power production, making them significant contributors to greenhouse gas emissions.

Boilers are generally quite efficient. As a result, it is difficult to reduce CO2 emissions simply by improving the combustion efficiency. Therefore, researchers are exploring alternative approaches to mitigating the environmental impact of CO2 emissions from boilers. One promising strategy to this end is to capture the CO2 emitted from these systems and convert it into a useful product, such as methane.

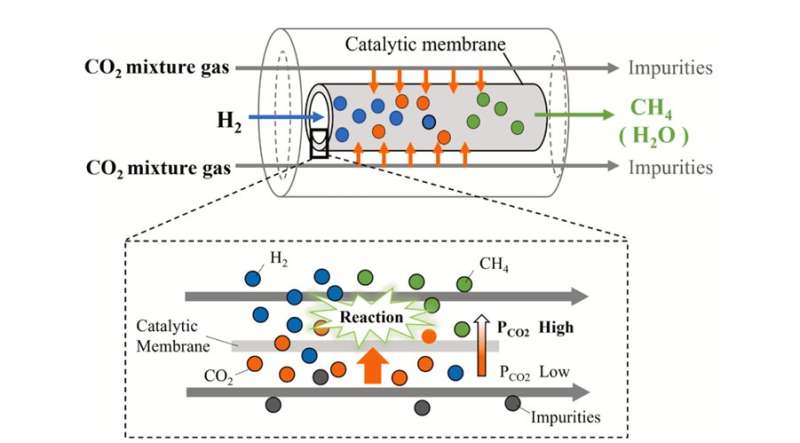

To implement this strategy, a specific type of membrane reactor, called the distributor-type membrane reactor (DMR), is needed that can facilitate chemical reactions as well as separate gases. While DMRs are used in certain industries, their application for converting CO2 into methane, especially in small-scale systems like boilers, has remained relatively unexplored.

This research gap was addressed by a group of researchers from Japan and Poland, who were led by Professor Mikihiro Nomura from Shibaura Institute of Technology in Japan and Prof. Grzegorz Brus from AGH University of Science and Technology in Poland. Their findings were published in the Journal of CO2 Utilization.

The team conducted a two-pronged approach to the problem through numerical simulations and experimental studies to optimize the reactor designs for efficient conversion of CO2 from small boilers into methane. In their simulation, the team modeled how gases flow and react under different conditions. In turn, this enabled them to minimize the temperature variations, ensuring that energy consumption is optimized while methane production remains dependable.

The team further found that, unlike traditional methods that channel gases into a single location, a distributed feed design could spread the gases out into the reactor instead of sending them in from one place. This, in turn, results in a better distribution of CO2 throughout the membrane, preventing any location from overheating.

"This DMR design helped us reduce temperature increments by about 300 degrees compared to the traditional packed bed reactor," explains Prof. Nomura.

Beyond the distributed feed design, the researchers also explored other factors influencing the reactor's efficiency and discovered that one key variable was the CO2 concentration in the mixture. Changing the amount of CO2 in the mixture affected how well the reaction worked.

"When the CO2 concentration was around 15%, similar to what comes out of the boilers, the reactor was much better at producing methane. In fact, it could produce about 1.5 times more methane compared to a regular reactor that only had pure CO2 to work with," says Prof. Nomura.

Additionally, the team investigated the impact of reactor size, finding that increasing the size of the reactor facilitated the availability of hydrogen for the reaction. There was, however, a tradeoff to be considered as the benefit of higher hydrogen availability required careful temperature management to avoid overheating.

The study thus presents a promising solution to the problem of tackling a major source of greenhouse gas emissions. By utilizing a DMR, low-concentration CO2 emissions can be successfully converted into usable methane fuel.

The benefits gained are not limited to methanation alone but can also be applied to other reactions, making this method a versatile tool for efficient CO2 utilization even for households and small factories.

More information: Yuya Sato et al, Unveil carbon dioxide recycling potential throughout distributor-type membrane reactor, Journal of CO2 Utilization (2024). DOI: 10.1016/j.jcou.2024.102763